CABERO Industrial Evaporative Condenser

A. CABERO INDUSTRIAL EVAPORATIVE CONDENSER

Product Description

The Jumbo V-shaped design (vertical air duct) is designed for use in industrial refrigeration and air conditioning technology, industrial cooling and power station cooling – especially for small available installation areas. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction. The heat exchanger technology allows the user a high degree of operational safety and the longevity of the product. This range of products maximizes and combines important ergonomic and economic aspects in practice: Compared with conventional competitive products, it provides the buyer with clear advantages in terms of purchase price and operating costs.

CONSTRUCTION METHOD

*Housing madeofFeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover(protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Normal to extremely quiet sound pressure levels

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Single-row and double-row fan positioning

*Fan intake chamber separated in pairs

*Smooth tubes

*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials

*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers and internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned

*Manufactured according to PED and ISO guidelines.

Product Description

The Jumbo V-shaped design (vertical air duct) is designed for use in industrial refrigeration and air conditioning technology, industrial cooling and power station cooling – especially for small available installation areas. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction. The heat exchanger technology allows the user a high degree of operational safety and the longevity of the product. This range of products maximizes and combines important ergonomic and economic aspects in practice: Compared with conventional competitive products, it provides the buyer with clear advantages in terms of purchase price and operating costs.

CONSTRUCTION METHOD

*Housing made of FeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover(protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Single-row and double-row fan positioning &*Fan intake chamber separated in pairs

*Smooth tubes &*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials &*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers and internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned

*Manufactured according to PED and ISO guidelines.

Product Description

The table construction (horizontal and vertical air duct) is designed for use in industrial refrigeration and air conditioning, industrial cooling and power station cooling. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction. The heat exchanger technology allows the user a high degree of operational safety and the longevity of the product. This range of products maximizes and combines important ergonomic and economic aspects in practice: Compared with conventional competitive products, it provides the buyer with clear advantages in terms of purchase price and operating costs.

Construction Method

*Housing made of FeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover (protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*R-profile (heat exchanger from 4200mm lamellierte length) can be easily separated from the fan housing

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Single-row and double-row fan positioning

*Fan intake chamber separated in pairs

*Smooth tubes

*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials

*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers & internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned

*Manufactured according to PED and ISO guidelines.

(iv) Sandwich Cooler Condenser& Re-cooler

Product Description

The table construction (horizontal and vertical air duct) is designed for use in the power generation industry. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction.

On request, this system can also be used in V-shaped devices. Mode of operation: Two superimposed heat exchangers allow the operation of two circuits. In this case, the lower temperature in the WT is positioned on the air inlet side. The heat exchanger technology allows the user a high degree of operational safety and the longevity of the product. This range of products maximizes and combines important ergonomic and economic aspects in practice: Compared with conventional competitive products, it provides the buyer with clear advantages in terms of purchase price and operating costs.

Design Type

*Housing made of FeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover(protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*R-profile (heat exchanger from 4200mm lamellierte length) can be easily separated from the fan housing

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Fan intake chamber separated in pairs

*Smooth tubes

*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials

*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers & internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned

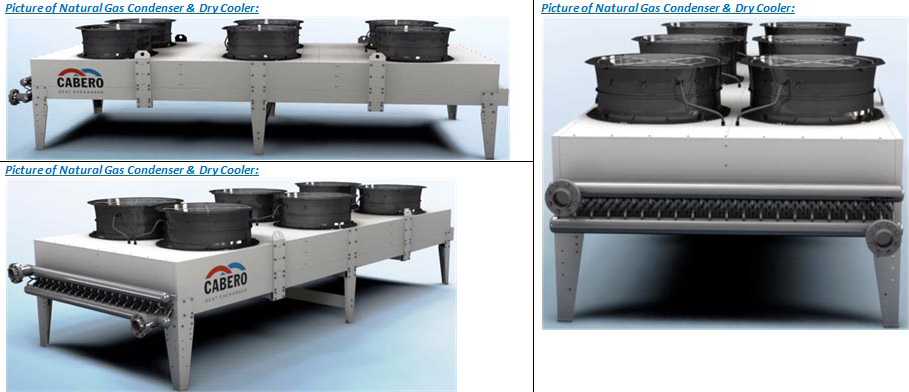

Product Description

The table construction (horizontal and vertical air duct) is designed for use in the petrochemical industry. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction. On request, this system can also be used in V-shaped devices.

How It Works

In order to achieve greater transport volumes (tanker cargo ships) or better pumping efficiency (pipeline), the gas is condensed under high pressure using the CABERO LNG condenser. The heat exchanger technology provides the user with a high degree of operational safety and longevity of the product. This range of products maximizes and combines in practice important ergonomic and economic aspects: Compared with conventional products of the competition, it provides the buyer with clear advantages in terms of purchase price and operating costs.

Design Type

*Housing made of FeZn *Powder-coated RAL 9010, cut edges painted

*Tube bends cover (protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*R-profile (heat exchanger from 4200mm lamellierte length) can be easily separated from the fan housing

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Fan intake chamber separated in pairs &*Smooth tubes

*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors &*All fixing materials made of stainless steel or corrosion-resistant materials.*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers & internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned.*Manufactured according to PED and ISO guidelines.

Product Description

The self-draining system in table construction (only vertical air duct) and conditionally V-shaped design is z. As used in industrial refrigeration and air conditioning, process cooling and power plants. The unique selling point is the independent emptying of the medium from the pipes – thanks to the heat exchanger, which is positioned diagonally in the housing, without any additional aids such as compressed air. The connection collectors are also tilted & a vent pipe is integrated in the highest point of the system. Application without antifreeze, so that z. B. in freezing conditions with the medium water internal icing in the pipes and thus damage is excluded.

Design Type

*Housing made of FeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover (protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*R-profile (heat exchanger from 4200mm lamellierte length) can be easily separated from the fan housing

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Fan intake chamber separated in pairs

*Smooth tubes

*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials

*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers & internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned

*Manufactured according to PED and ISO guidelines.

Product Description

The hybrid construction (vertical air duct) is designed for use in industrial refrigeration and air conditioning, industrial cooling and power station cooling – especially with very small available installation areas and large cooling capacities. A special selling point is, in addition to the use of well-known quality fans and the optimal choice of materials, the very high quality and stable construction.

The heat exchanger technology allows the user a high degree of operational safety and the longevity of the product. This range of products maximizes and combines important ergonomic and economic aspects in practice: Compared with conventional competitive products, it provides the buyer with clear advantages in terms of purchase price and operating costs.

Design Type

*Housing made of FeZn

*Powder-coated RAL 9010, cut edges painted

*Tube bends cover (protection against contact)

*Optimized, top-mounted fan housing for improved fan efficiency

*STES (Safety Tube Expanding System) floating tube system (tube has no contact with plates), therefore no possibility of leaks during trans- port and operation

*Normal to extremely quiet sound pressure levels

*Maintenance-free axial fans with diameter 800-1000 mm – ErP 2015 compliant (for Europe)

*Single-row and double-row fan positioning

*Fan intake chamber separated in pairs

*Smooth tubes &*Smooth fin surface (less contamination, best possible cleaning)

*Flanged or threaded connectors

*All fixing materials made of stainless steel or corrosion-resistant materials

*Container-optimized ranges

*Sturdy design through R-profile longitudinal stabilizers and internal reinforcing units, virtually no torsion and no bending (high operational safety and therefore long service life)

*Crane lugs can be removed and repositioned &*Manufactured according to PED and ISO guidelines.

Product Description

CABERO, a leading producer in Heat Exchangers for refrigeration and air-conditioning technology our industry experts offer innovative solutions and continue to develop in the latest innovation including the DUO range. Be one of the first in UK and talk to us about the features:

The Most Important Of The New DUO - At a Glance

Mostly there is no water treatment necessary (supplied water).

CABERO Turbo Plus completely or per segment interchangeable.

High efficiency rating due to CABERO turbo plus technology.

Outlet glycol/water temperature 2-3K over WB (Hybrid Normally 4-5K).

Extraordinary high operation safety.

Very favorable operating costs.

High saving of the resources of water and energy.

Operation & Temperature Range

Design on wet bulb: 20-25°C,

Dry/Wet changeover approx.: 9-22°C,

Medium outlet temperature from approx. 2-3 K over wet bulb,

Fins: not protected,

Operation security: high,

Applications (depending on the temperature level): Chillers, Absorber, Industrial and process cooling

Product Description

For more than 30 years, CABERO has been offering plant builders and planners a wide, practice-oriented product range. Numerous, partially patented further developments provide a tailor-made, highly efficient solution for almost every application. As a leading manufacturer of adiabatic systems for condensers and re-coolers for cooling media, NH³ and refrigerants, CABERO has only one goal: to largely save the available resources and to find an economically and ecologically optimal solution for the entire plant.

Water Quality Demands on the water quality of adiabatic systems LPSS and HPSS

Copper (Cu) must not be detectable in the make-up water. Iron (Fe) should not be present. It should also be noted that the chemicals used do not cause stress corrosion on the materials used in the heat exchanger or even damage them. If the recommended water quality is maintained & the recommended treatment products are used, deposits, corrosion and microbiological contamination are not or only minimally expected. You can request water softening systems, reverse osmosis, dosing technology and the maintenance of such systems, for example, from Schweitzer-Chemie GmbH in 71691 Freiberg /Neckar. Hygiene requirements of VDI 2047 Part 2 must be observed. Accordingly, the inspection intervals of the inspections and the water quality must be observed and additionally transmitted to the company CABERO heat exchangers. In the case of deviating water values, appropriate countermeasures must be taken immediately and wetting is prohibited in this case. If the registration times are not met, CABERO has the right to refuse warranty service. Fall out should be initiated in rainwater drainage or in the sewage. Biocides on an oxidizing basis are not permitted. (As of 01/2018) Adiabatic Hygiene Certificate Vdi 6022 En

Product Description

CABERO ECOPAD systems complete the range of evaporative coolers and adiabats. Thus, CABERO is one of the few manufacturers to cover all systems in the sector of evaporative and adiabatic coolers and to offer you unique solutions and planning aids, without having to emphasize any product policy. To largely save the available resources and to find an economically and ecologically optimal solution for the entire plant was also a central theme in the new development of the CABERO ECOPAD. Cabero’s main purpose in the ECOPAD system was to improve and redefine the benefits of the system. PAD systems generally have their advantages in that the spray water does not come into contact with the heat exchanger, hardly have aerosols in the air and the CABERO ECOPAD systems complete the range of evaporative coolers and adiabats. Thus, CABERO is one of the few manufacturers to cover all systems in the sector of evaporative and adiabatic coolers and to offer you unique solutions and planning aids, without having to emphasize any product policy. The decision whether to use a hydrophobic or hydrophilic PAD structure is due to the quality of the water and will be adapted in individual cases to the customer’s wishes. Hydrophobic PAD structures have significantly less efficient evaporative cooling than hydrophilic structures. However, they are more resistant to pollution and easier to clean.

Method of Construction

Closed circuit

Properties

Higher investment costs than the adiabatic cooler,

Low operating costs (higher energy consumption of the fan)

42. Bim SchV is relevant (Pollution Control Ordinance)

Operation possible at 14 ° dH and 1000 micro Siemens

No mist removal

Operation: dry approx. 95% / wet 5%

Operation and Temperature Range: (preferred operation of the dry cooler)

Capacity: up to 1,500 Kw, Wet bulb: 21-25 °C , Dry / wet switching at approx. 22 ° -26 ° C, Slats are unprotected, Average outlet temperature from approx. 28 – 30 ° C , Operational safety: high.

Application (depending on the temperature level)

Radiator, absorber, industrial and process cooling.