CABERO Industrial Air-Cooler (Cooling Unit)

A. CABERO INDUSTRIAL EVAPORATORS & AIR-COOLERSFOR COMMERCIAL PURPOSE

(i) (Ceiling evaporators & Air cooler)

Product Description

The CABERO “Professional Industrial Line”, which is very price-attractive, is mainly used in the business areas of large commercial refrigeration, as well as in industrial refrigeration. Particularly the flow pipe divisions as well as the appropriate performance spectrum ensure the user with low weight losses and significantly lower optical impairments of the refrigerated goods, even when long-term storage of fresh and sensitive products (such as meat, fish, vegetables, fruits, flowers etc.). The likewise minimized weight loss in the refrigerated goods is achieved in these units by keeping the average surface temperature of the lamella more constant and in a smaller spreading to the inlet temperature. This allows a considerably lower air dehumidification, as well as the frost is minimized and controlled. In the case of low-temperature applications, these advantages are significantly visible, in particular by significantly lower defrosting frequency True to the company motto “engineered to succeed.”, This applied technology in the industrial air coolers helps to put the added value of the user at the center of the technology – at a very attractive price at the same time.es, small icing of the heat exchanger, as well as more constant throwing distances compared to the offset pipe division, leading to a significant reduction in the energy costs of the plant.

CABERO INDUSTRIAL EVAPORATORS & AIR-COOLERSFOR COMMERCIAL PURPOSE

ii) (Fruit & vegetable Evaporator & Air cooler)

Product Description

The CABERO “Professional Industrial Line”, which is very price-attractive, is mainly used in the business areas of large commercial refrigeration, as well as in industrial refrigeration. Particularly the flow pipe divisions as well as the appropriate performance spectrum ensure the user with low weight losses and significantly lower optical impairments of the refrigerated goods, even when long-term storage of fresh and sensitive products (such as meat, fish, vegetables, fruits, flowers etc.). The likewise minimized weight loss in the refrigerated goods is achieved in these units by keeping the average surface temperature of the lamella more constant and in a smaller spreading to the inlet temperature. This allows a considerably lower air dehumidification, as well as the frost is minimized and “controlled”. In the case of low-temperature applications, these advantages are significantly visible, in particular by significantly lower defrosting frequencies, small icing of the heat exchanger, as well as more constant throwing distances compared to the offset pipe division, leading to a significant reduction in the energy costs of the plant. True to the company motto “engineered to succeed.”, This applied technology in the industrial air coolers helps to put the added value of the user at the center of the technology – at a very attractive price at the same time.

B. CABERO INDUSTRIAL EVAPORATORS & AIR-COOLERSFOR COMMERCIAL PURPOSE

(i).(Shock Frosters Evaporator & Air cooler)

Product Description

The CABERO shock-freezers are used where fast and large freezing capacities are critical and required in a confined space. These air coolers series (also customer-specific designs possible) are used for rapid cooling and shock in the food industry The operator – usually a food processor – can be equipped with a highly ergonomic, economical and cost-effective method for the installation (cooling or shocking of meat, fish, poultry, ready-to-serve meals, dairy products) Reliable air cooler, which largely secures the core business of the operator, and maximizes its “economic added value”.

(ii) Insulated coolers Evaporator & Air cooler

Product Description

Operation: The evaporators or air coolers are installed in the heat-insulated cells at the factory. These heat-insulated cells are installed outside the storage room and “flanged” to the building with a breakthrough on the air side. As a result, the connection can be separated from the heat-insulated cell to the cooling chamber in the defrosting process by means of the folding system. The temperature of the circulating air corresponds to the type of defrosting – here we distinguish between brine &hot gas defrosting as well as electrical defrosting. This allows service & maintenance work under recirculated air temperatures.

(iii) Enthouse cooler Evaporator & Air cooler

Product Description

Operation: The evaporators or air coolers are installed in the heat-insulated cells at the factory. These heat-insulated cells are installed outside the storage room and “flanged”to the building with a breakthrough on the air side.As a result; the connection can be separated from the heat-insulated cell to the cooling chamber in the defrosting process by means of the folding system. The temperature of the circulating air corresponds to the type of defrosting – here we distinguish between brine and hot gas defrosting as well as electrical defrosting. This allows service and maintenance work under recirculated air temperatures.

Energy efficiency

The flap system is closed before the defrosting process. As a result, accumulated steam swells and resulting ice formation in the storage space can be completely excluded. During the defrosting process, a heat and moisture input into the storage space (cooling room) is avoided, thus achieving maximum energy efficiency. The folding system mounted on the heat exchanger or in the air duct system of the heat exchanger almost prevents the heat input during the defrosting process into the storage space (cooling room). The valves are controlled by a CABERO controller or by an external signal from the customer system. In the case of modernization or building renovation, these systems can guarantee very short installation times due to the factory assembly.

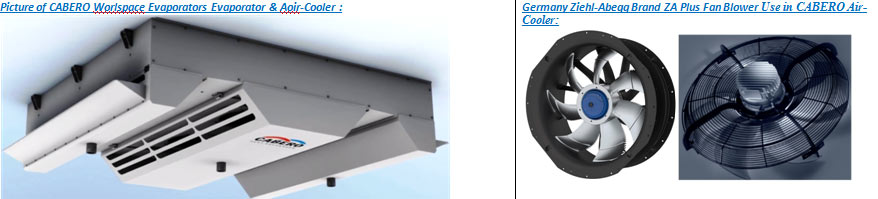

(iv).Workspace evaporators Evaporator & Air cooler

Product Description (Workspace Evaporator)

DEFROSTING: Electric, hot gas or brine

CONSTRUCTION METHOD:

Folding drip trays with quick-release enable access to all components, and thus easy cleaning and inspection

Height-adjustable ceiling hangers

Welded condensate drains

Housing made of AlMg3, powder coated in RAL 9010

Cut edges painted

C. CABERO INDUSTRIAL EVAPORATORS & AIR-COOLERS

(i). Medium Capacity Range

(ii). CABERO HEAVY DUTY INDUSTRIAL EVAPORATORS & AIR-COOLERS:

(iii). CABERO HEAVY DUTY INDUSTRIAL EVAPORATORS & AIR-COOLERS

Product Description

Those in refrigeration Air coolers in use differ between pressing and sucking versions via the heat exchanger package (heat exchanger block). In the sucking version, the fan is located in the cooled air stream, so that the heat load of the fan is supplied to the cooled air stream and heats it. At the same time, the relative humidity of the airflow is lowered. In the pressurized version, the fan is in the air flow in front of the heat exchanger package, so that the heat load of the fan is taken into account in the cooling process of the air cooler and the relative humidity can be kept almost constant, contrary to the suction design. Since a high relative humidity in the air flow is crucial for the water balance and the transpiration of the product CABERO fruit and vegetable chillers are designed in an oppressive way, in order to be able to counteract even the slightest negative influences on the chilled product. Depending on the application, optimized lamella geometries and coordinated lamellar spacings are used to fully comply with the conditions of the product and its storage. Due to the large heat exchange surfaces and the adjusted air volume flows, CABERO fruit and vegetable coolers can represent a very low Dt (Dt = evaporation temperature or ethylene glycol inlet temperature – air inlet temperature). This is the deciding factor for the very low dehumidification of the storage products and for the preservation of the quality of the product, the goal of protecting and optimizing the intrinsic value of your core business is more than met with the new CABERO fruit and vegetable coolers – in line with our company motto: engineered to succeed.

DEFROSTING - Electric, Hot Gas, Brine or Water

DESIGN TYPE:

Air baffle at the air outlet to increase the air flow

Slim Line – flat housing construction

Welded condensate drains

Housing FeZ, tub AlMg3

Powder coated in RAL 9010

Lacquered edges

Escaping pipe pitch and large lamella exchange surfaces for less air dehumidification and less ice formation. This means less weight and quality loss when refrigerated.