Dyeing Machine

Beam Dyeing Machine

Product Description

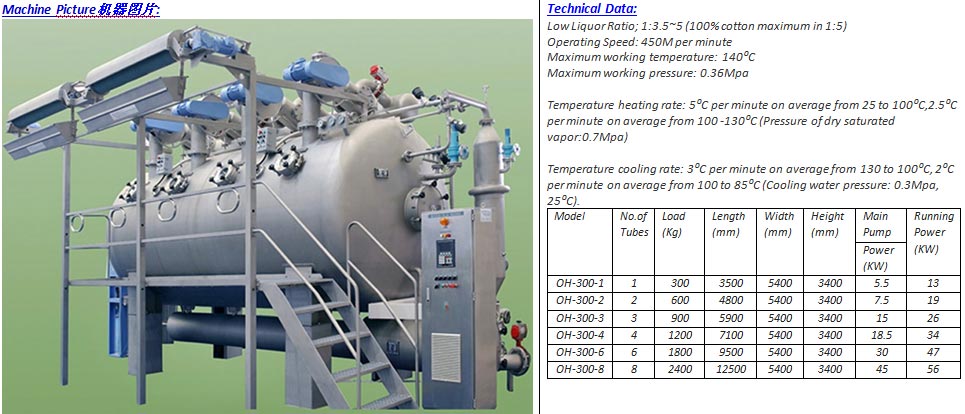

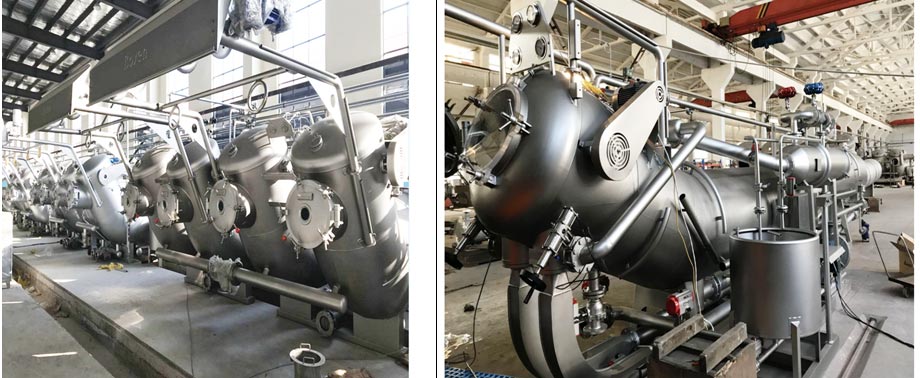

OH series low liquor ratio, low power consumption, low maintenance cost, high-temperature high pressure overflow fabric dyeing machine is suitable for the scouring/bleaching/dyeing/washing of all types of knitted and woven fabrics :Cotton,Modal,Viscose,Tencel,Rayon,Wool,Acrylic,Lyocell,Nylon,Polyester blended and lycra blended,etc.

产品描述:

OH系列低浴比,低功耗,低维护成本,高温高压溢流织物染色机适用于各类针织和梭织面料的精练/漂白/染色/洗涤:棉,莫代尔,粘胶,天丝 ,人造丝,羊毛,腈纶,Lyocell,尼龙,涤纶混纺和莱卡混纺等。

Machine is designed and manufactured in accordance with pressure vessel standards GB 150, with maximum working temperature of 140 °C and maximum working pressure of 0.36 MPa. All parts in touch with dye liquor is made of corrosion-resistant stainless steel S31603 (316L) material. With a specially-designed nozzle structure, it enables the fabrics in loose and expanded conditions during the dyeing process. It has an excellent performance in dyeing tight and heavy fabrics and can eliminate the crease mark problem, which is usually seen in other dyeing machines. Meanwhile, the machine has two ropes loading capability.

该机器按照 GB 150压力容器标准设计和制造,最高工作温度为 140⁰C,最大工作压力为 0.36 Mpa。 所有与染液接触的par BS均采用耐腐蚀不锈钢S31603(316L)

材料制成。采用特殊设计的喷嘴结构,使织物在染色过程中处于松散和膨胀状态。它在染色紧密和重型织物方面具有优异的性能,并且可以消除其他染色机中常见的折痕问题。 同时,该机器具有两种绳索装载能力。

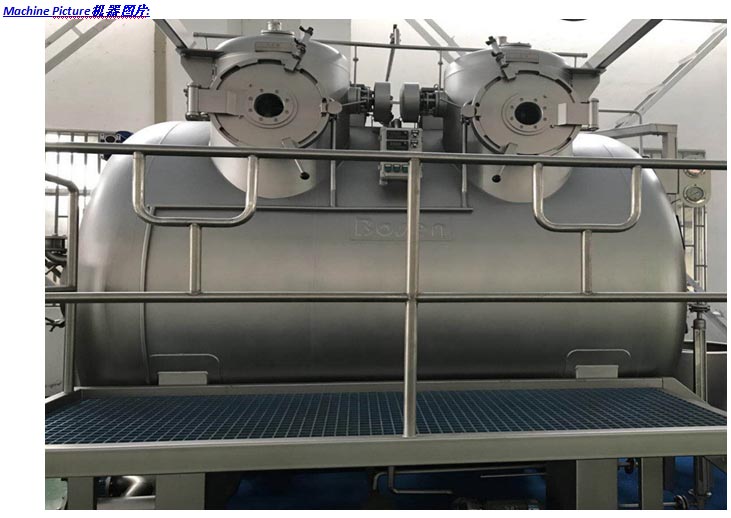

Machine Picture

2. Low Liquor Ratio High-Temperature Overflow Dyeing Machine: Model: OH Series

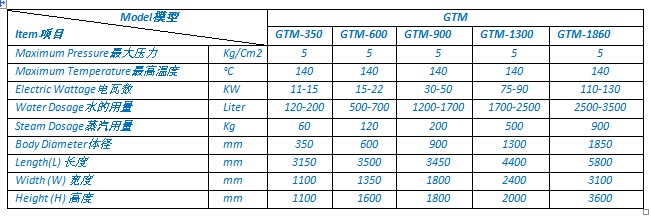

3. Textile Machinery Low Power Consumption Dyeing Machine: Model: GTM

Product Description & Purpose

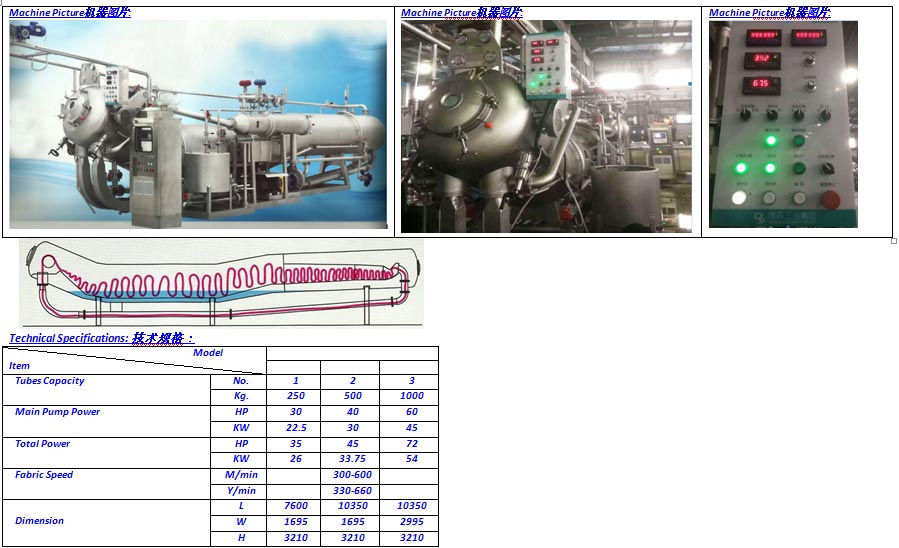

GTM high-temperature multipurpose beam dyeing machine is mainly used for economical dyeing of various fibers. It is applicable to dye, bleach and preliminarily treat open width fabric with non tension. It supplies the best conditions of dyeing and bleaching for sensitive fabric, tatting fabric, knitted fabric, non-woven fabric and easy-deformed, easy-rolled fabric.

目的:GTM高温多用途染色机主要用于各种纤维的经济染色。适用于染色,漂白和初步处理无张力的宽幅织物。它为敏感织物,梭织面料,针织面料,无纺布和易变形易卷织物提供最佳的染色和漂白条件。

Main Features:主要特点:

1.Wide application; it is applicable to nylon, Tatian silk, noble silk, silk broadcloth, bright silk, plain woven fabric, polyester fabric, Lanka stretch fabric, Oxford, computerized embroidery lace fabric and warp-knitting fabric.

1.广泛的应用; 适用于尼龙,塔丝绸,贵族丝绸,丝绸宽幅,亮丝,平纹织物,涤纶织物,兰卡弹力织物,牛津,电脑刺绣蕾丝面料和经编面料

2.Reasonable sampling device for sub sample with easy set and handy sampling.

2.适用于子样品的合理采样装置,易于设置和方便采样。

3.Adjustable loop structure to ensure the adjustment of various breadth fabrics.

3.可调节的环形结构,确保各种宽幅织物的调整。

4.The special computer of GTM dyeing machine is easy to control, during dyeing, raising and decreasing temperature, filling, draining, washing, charging and inside and outside pressure difference set can be full automatic operation, as a result the negligence by operators is reduced.

4.GTM染色机专用电脑易于控制,染色,升温,降温,灌装,排水,清洗,充电,内外压差设定均可全自动操作,操作人员疏忽大意。降低。

5. Five, computer flow control, full automatic acid system, PH online detection.

5.五,计算机流量控制,全自动酸系统,PH在线检测。

6. The diameter of dyeing vessel is up to Φ400mm~Φ1600mm, the breadth of fabric and the required length of cylinder are designed in according with user’s demands.

6,染色容器直径达Φ400mm~Φ1600mm,根据用户要求设计织物宽度和所需长度。

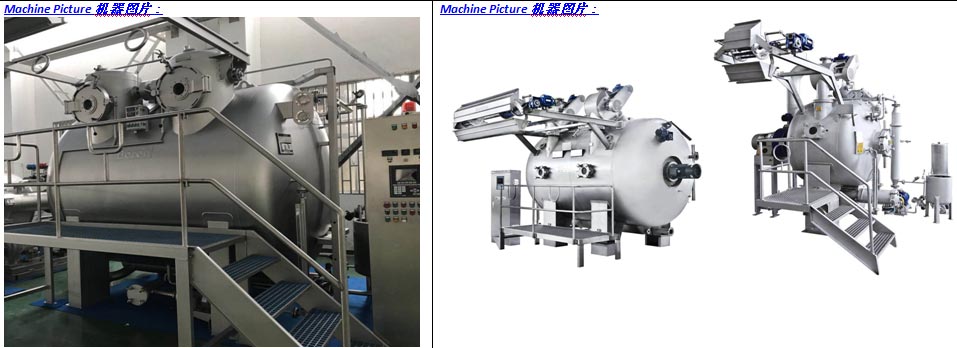

4. Textile Machinery Low Power Consumption Dyeing Machine: Model: GTM

HTHP AIR FLOW DYEING MACHINE

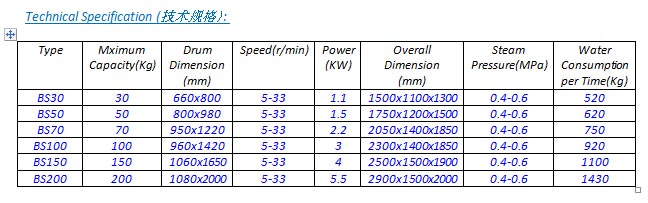

1. Constant Temperature Dyeing Machinery Pringting Machine for Textile

Product Description

1. Liquor ratio of 1:4-5 and smooth fabric running are maintained within 70-100% capacity.

2. Fabric speed up to 350m/min.

3.Jumbo capacity up to 250kg/tube

4. MSR Multi-saving rinsing system.

5. MIR Multi-function intelligent rinsing system, realizes no-drop bath dyeing technique without machine stopped.

产品描述:

1. 1:4-5的比例和平滑的织物运行保持在70-100%的容量

2.Fabric速度可达350m / min

3.巨型容量可达250kg /管

4.MSR多节水冲洗系统

5.MIR多功能智能漂洗系统,无需停机即可实现无滴浴染色技术。

2. Ce Passed Dyeing Yarn Equipment Knitting Machinery Textile Machine Model NO.: GTM350-GTM1860

(1) It is suitable for bleaching, refining, dyeing, washing and post-treatment of gauze yarn, embroidery thread, silk and nylon hank or tape.

2) The machine uses a specially designed low-power, low head, large flow axial flow pump. High temperature does not affect its characteristics.

3) The new weir-flow injection tube, dyeing tube and turning yarn shift tube into one, the dye is absolutely no bite yarn winding or knotting phenomenon, easy to reverse the staining, the loss rate is low.

4) Special design water regulator visual yarn count and the yarn count, different types, the size of any regulation of water.

5) Structure optimization, bath ratio is small, saving raw materials and reduces cost.

特征:

1)适用于纱线,绣花线,丝绸,尼龙绞线或胶带的漂白,精制,染色,洗涤和后处理。

2)该机采用专门设计的低功率,低扬程,大流量轴流泵。 高温不会影响其特性。

3)新型堰流注射管,染色管和转纱移管成一体,染料绝对没有咬纱缠绕或打结现象,易于反转染色,损失率低。

4)特殊设计水调节器可视纱支数和纱支数,不同类型,任何调节水的尺寸。

5)结构优化,浴比小,节省原材料,降低成本。

1) Body: High-quality high-corrosion-resistant stainless steel

2) Spray tube: high corrosion-resistant stainless steel plate manufacturing

3) Reliable PLC program controller

4) Automatic opening system

5) Machine design of multiple sets High-performance stainless steel axial flow pump of security operating system

6) Easy to install yarn, yarn, cleaning nozzle tools

标准结构:

1)机身:优质高耐腐蚀不锈钢

2)喷涂管:高耐腐蚀不锈钢板制造

3)高性能不锈钢轴流泵

4)可靠的PLC程序控制器

5)自动开启系统

6)多套安全操作系统的机器设计

2. Ce Passed Dyeing Yarn Equipment Knitting Machinery Textile Machine Model NO.: GTM350-GTM1860

1) Design pressure: 0.44Mpa

2) Maximum working pressure: 0.4Mpa

3) Design temperature: 140 ⁰C

4) Maximum operating temperature: 135 ⁰C

5) Effective length of hanging yarn: 1200-1500mm

6) Suitable length of hank: 820mm

7) Bath ratio: 1: 8-12

8) Heating rate: 20 ⁰C ~ 130 ⁰C for about 30 minutes (saturated steam pressure value of 0.7Mpa)

9) Cooling rate: 130 ⁰C to 80 ⁰C for about 20 minutes

3. Fabric Overflow Dyeing Machine : Model: AGBI Series--H.T.&H.P.

Product Description & Structure Features

1. circulation, ideal dyeing effect:With a maximum speed of 360m/min, fabrics move fast inside the chamber. The liquor is meanwhile separated effectively so as to enhance the circulation of fabrics and liquor. The homogenous dyeing liquor infiltrates into fabrics frequently which result in a better dyeing effect.

2. Double nozzles transit the cloth in overflowing model, reach favorable dyeing effect. The unique designing of the overflow nozzle works together with the fabric-lifting wheel to drive the fabric moving. Fabrics float inside the nozzle in a natural manner. Fuzzy main problem is thus avoided.

3. Innovative fabric accumulator with large capacity and low liquor ratio the innovative fabric accumulator is designed in a curve shape with Teflon tubes distributed at the bottom of the chamber. This designing allows a bigger space for larger capacity and smoother fabric movement. At the same time, this innovative designing can secondarily separate the liquor from fabrics. The dyeing liquor is thus circulated faster and a lower liquor ratio is achieved.

织物溢流染色机结构特点:

1.循环,理想的染色效果。最高速度为360米/分钟,织物在腔室内快速移动。同时有效地分离液体,以增强织物和液体的循环。均匀的染色液经常渗透到织物中,从而产生更好的染色效果。

2.双喷嘴在溢流模型中过滤布,达到良好的染色效果。溢流喷嘴的独特设计与织物提升轮一起工作,以驱动织物移动。织物以自然的方式漂浮在喷嘴内。因此避免了模糊 问题。

3.创新的织物蓄能器,具有大容量和低浴比新的织物蓄能器设计成曲线形, Teflon管分布在腔室底部.这种设计允许更大的空间, 更大的容量和更平滑的织物运动.同时,新的织物蓄能这种创新设计可以二次将酒与织物分开.因此,染色液更快地循环并且实现更低的浴比。

Standard structure and parts :

1 Machine body made of anti-corrosive high quality S.S.

2 Fabric lifting system with inverter, 50-360m/min.

3 Circular dual-Made nozzle.

4 Fabric-liquor separating and collecting system.

5 Effective S.S. centrifugal pump with mechanical seal.

6 Main pump speed inverter or flow regulating valve.

7 Pneumatic valve controls heating, cooling, water inlet, outlet and ringing.

8 Heat exchanger. 9 Internal cleaning system. 10 Water level indicator.11 Operator-friendly feeding system. 12 Main control panel equipped with advanced micro-processer.

13 Working platform. 14 Fabric unloading device. 15 Main body pressurizing and depressurizing system.

标准结构和 parts:

1.机身由耐腐蚀的高品质S.S.制成。

2.带变频器的织物升降系统,50-360m / min。

3.圆形双Made喷嘴。

4.织物 – 液体分离和收集系统。

5.带有机械密封的有效S.S.离心泵

6.主泵速变频器或流量调节阀.

7.气动阀控制加热,冷却,进水,出水和振铃。

8.换热器。9.内部清洁系统.10.水位指示器..11.操作员友好的喂食系统。12.主控制面板配备先进的微处理器.

13.工作平台.14.织物卸料装置。15.主体加压和减压系统。

3. Fabric Overflow Dyeing Machine : Model: AGBI Series--H.T.&H.P.

Options

Steam detector

Quantitative feeding system with feeding pump

Proportional heating and cooling system

Secondary water inlet and outlet.

Fabric unloading device with plaiter

Hot water tank

选项

接缝探测器

带进料泵的定量给料系统

比例加热和冷却系统

二次进水口和出水口。

织物卸料装置有刨刀

热水箱

Technical Data

Max. working pressure:3.5bar

Max. working temperature:140⁰C

3.5⁰C/min (25–130⁰C, 7bar steam.)

Cooling rate: 2.5⁰C/min (130–80⁰C, 3bar cooling water pressure).

技术数据

最大。 工作压力:3.5bar

最大。 工作温度:140ºC

3.5⁰C/ min(25-130ºC,7bar蒸汽。)

冷却速度:2.5ºC/ min(130–80ºC,3bar冷却水压力)。

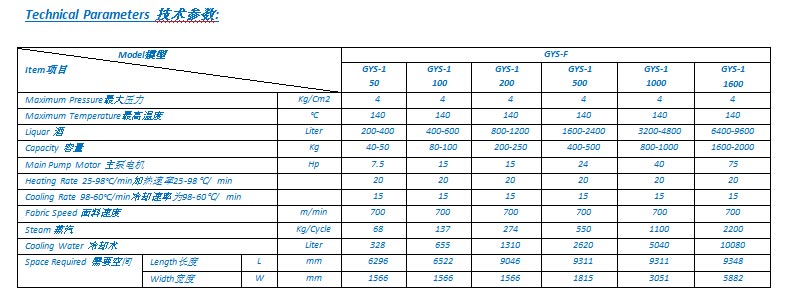

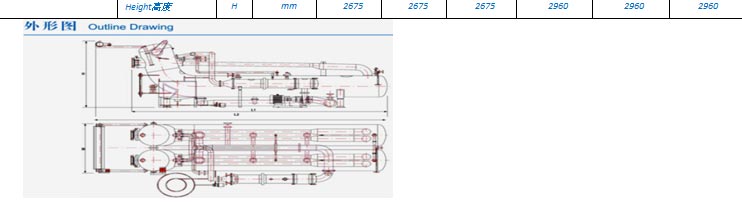

4. Model GYS-F High Temperature and High Rapid Dyeing Machine

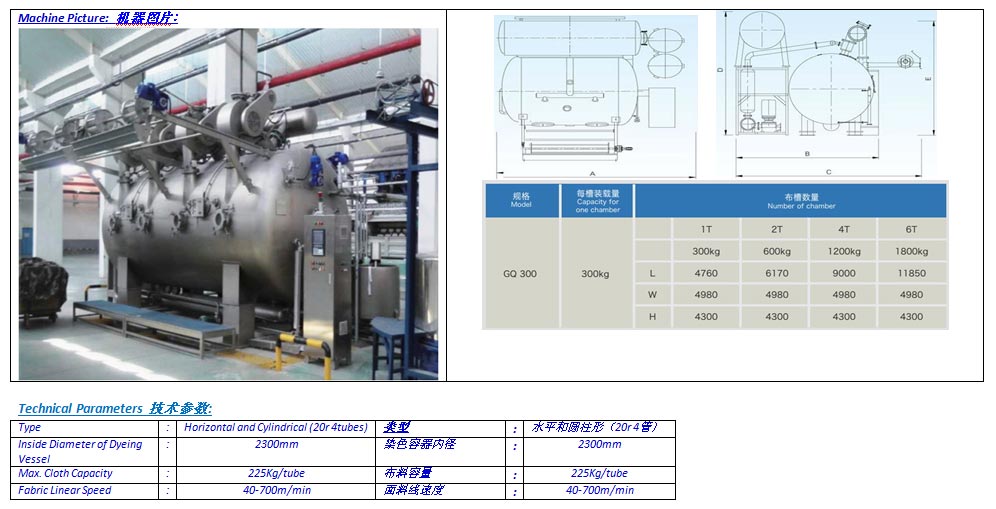

5. GQ Series Air Flow Dyeing Machine

Product Description & Purpose

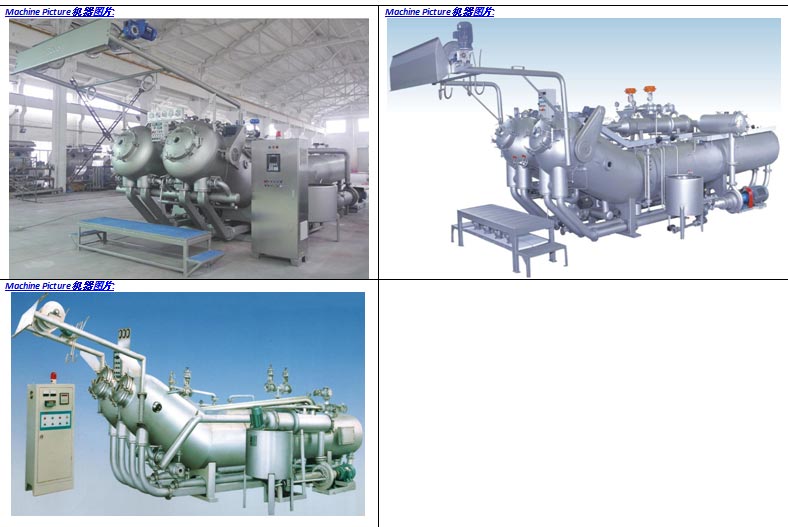

Air power and airflow dyeing atomize the mixed air flow of the airflow and overflow in nozzle. Because of no liquid circulation, the ultralow bath ratio of dyeing liquid comes true. So we can dye fabrics in spray pattern of dyeing liquid which suits for cottons, mixed fabric, blended fabric, ultrafine fabric and chemical facsimile fabric. This machine has high automation, high efficient environment protection, saving energy. Compared with common jet dyeing machines, it can save water around 50% and shorten dyeing time about 50% more with high dyeing efficiency and good reappearance.

目的::

空气动力和气流染色雾化气流的混合气流并在喷嘴中溢出。由于没有液体循环,染色液的超低浴比实现。因此我们可以在适合棉,混纺织物,混纺织物,超细织物和化学传真织物的染色液喷雾模式中染色织物。该机具有自动化程度高,环保高效,节约能源的特点。与普通喷射染色机相比,染色效率高,再现性好,可节约水分50%左右,染色时间缩短50%左右。

The equipment is of high efficiency, low bath ratio; low tension and transmission speed of airflow fabric is more than 350m/min. The bath ratio of cotton fabric is 1:4, the bath ratio polyester fabric dyed is 1:2. Low liquid volume, slight weight and small tension are companioned with the fabrics when driving.

该设备具有高效率,低浴比,低张力,气流织物传输速度大于350m / min。 棉织物的浴比为1:4,浴比为涤纶织物染色为1:2。 驱动时织物的液体体积小,重量轻,张力小。

Scratch-proof, anti-block, airflow inclined pipe using dyeing overflow make the fabrics float. Spray device is set up in outlet of airflow inclined pipe using dyeing liquid to rock fabric and polytetrafluoroethylene to cover the fabric in storage area.

采用染色溢流的防刮,防堵,气流倾斜管使织物漂浮。喷气装置设置在气流倾斜管的出口处,使用染色液对岩石织物和聚四氟乙烯覆盖储存区域的织物。

It can filled and discharge under the condition of high temperature and high pressure. During waste water discharge, fill in clean water with high efficiency washing.

它可以在高温高压条件下进行充放电。 在废水排放过程中,加入清水,高效洗涤。

The variable speed of the computer’s frequency conversion program, drive roll, fan, circulation pump and dyeing are automatic controlled.

计算机的变频程序,驱动辊,风扇,循环泵和染色的变速是自动控制的

Special Computer for advanced inlet airflow dyeing machine, with flexibility, convenient, programmable, modification, storage and high precision temperature self-control. Fine dyeing technical control and centre control.

专用于先进的进气流式染色机,具有灵活,方便,可编程,改装,储存和高精度温度自控功能。 精细染色技术控制和centre控制。

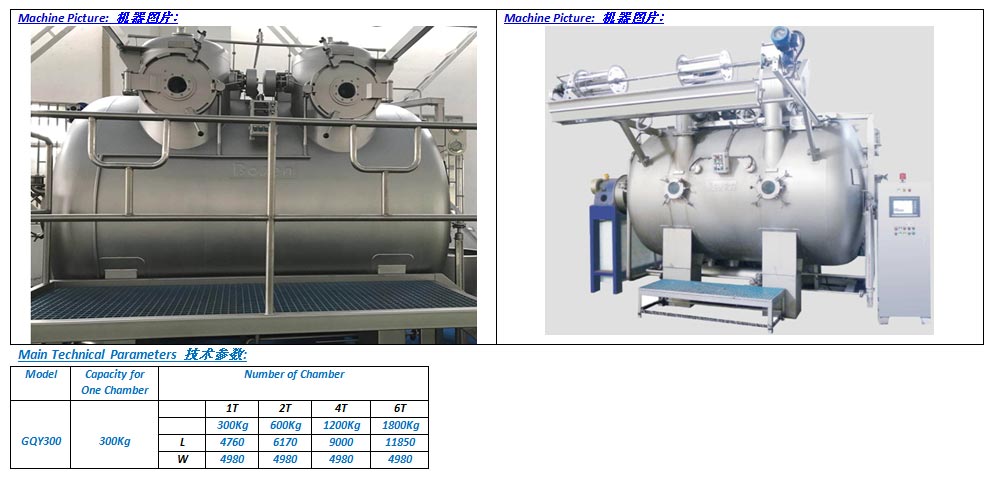

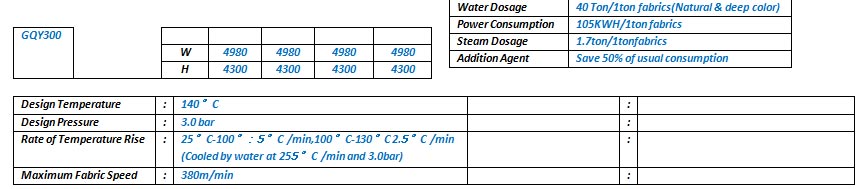

7. GQY Series of Air-Liquid Dyeing Machine Chinese

Product Description:

GQY series of air-liquid dyeing machine On the current market, the old air-liquid dyeing machines have many problems, such as drawback and limitation in the principle of the machine, the ability of fluff and level dyeing which are weaker than overflow dyeing machine. So Bosen industry has developed a new generation of patented design air-liquid dyeing machine. This air-liquid dyeing machine is highly efficient and energy-saving, besides, it can meet the requirements of dyeing process, it is still fit for dyeing the heavy weight and tight fabric. In the meantime, it has overcome the difficult problem perfectly of air-liquid dyeing machine for difficult washing. All these advantages of the new air-liquid dyeing machine broaden the road to sustainable development and are also a major and transformational breakthrough in dyeing and finishing industry.

产品描述:

GQY系列气液染色机在目前的市场上,旧的气液染色机存在许多问题,例如机器原理的缺点和局限性,比绒毛染色机弱的绒毛和均匀染色能力。此博森工业开发了新一代专利设计的气液染色机。该气液染色机效率高,节能,可满足染色工艺要求,适用于重型,紧密织物的染色。同时,它彻底克服了气液染色机难以洗涤的难题。新型气液染色机的所有这些优势拓宽了可持续发展的道路,也是染整行业的重大突破性突破。

Product Characteristics:

Innovative Model:

Atomization and pure overflow can fuse and alternate perfectly. The machine is taking into account the difference between the conventional knitted fabric and the heavy weight and tight fabric. The water ratio is as low as 1:3.5; it is very energy-saving. Parameters follows:

创新模式:

雾化和纯溢流可以完美融合和交替。 该机器考虑了传统针织面料与重量和紧身面料之间的差异。 水比低至1:3.5; 它非常节能。 参数如下

High -Efficiency Fan:

The machine is equipped with a novel and curved fan. When increasing the wind pressure substantially, the power of the machine will reduce to15KW, which is ahead of the similar dyeing machine in the matter of energy consumption.

我高效的风扇:

该机器配备了新颖的弧形风扇。 当大大增加风压时,机器的功率将降低到15KW,这在能耗方面领先于类似的染色机。

Super water washing:

The machine has dual-nozzle washing function in the front and back, so the water wash efficiency is enhanced much more, which can save 50% of the washing time compared with the similar dyeing machine. Moreover, the cylinder is equipped with washing controlling computer without dead-zone that is saving both time and effort.

超级水洗:

本机前后均采用双喷嘴清洗功能,水洗效率提高,与同类染色机相比,可节省50%的洗涤时间。此外,气缸配备无死区的洗涤控制计算机,既省时又省力。

Excellent capacity:

The capacity of each chamber can reach to 300-350 kg.

出色的容量 每个:

腔室的容量可以达到300-350千克。

Fully intelligent Control:

The machine can intake and drain water automatically, besides, it has automatic cleaning system, intelligent washing system, system of detecting fabric’s head, automatic cooling system and so on.

完全智能控制 该机可:

自动进水和排水,并具有自动清洗系统,智能清洗系统,检测织物头系统,自动冷却系统等。

8. High Pressure Textile Air Flow Dyeing Machinery Finishing Machine: Model NO.: GTM350-GTM1860

Product Description:

High Pressure Textile Dyeing Machines, Rotary Refining Preshrinking Crepe Washing Machine. This machine is produced on the basis of digestion and absorption of foreign advanced similar products. It is a high temperature and high pressure refining equipment, compact structure, good effect and high device of automation.

产品描述:

高压纺织染色机旋转精炼Preshrinking皱纹洗衣机该机是在消化吸收国外先进同类产品的基础上生产的。是一种高温高压精炼设备,结构紧凑,效果好,自动化程度高。

Application:

This machine is mainly suitable for polyester, spun silk productc, in the condition of no tension ,desizing preshrinking , crepe.It can also be used in the chemical fabric desizing, can fully remove the oil on the fiber and the sizing agent on the wrap to ensure that the fiber make good contact with alkali agent.The machine can equip computers according to users’ requirements ,simple operation,large capacity,is the best choice to replace imported products.

应用:

本机主要适用于涤纶,绢丝制品,在无张力,退浆,预缩,绉的条件下。也可用于化学织物退浆,可以充分去除纤维上的油和包装上的上浆剂 保纤维与碱剂接触良好。

本机可根据用户要求配备电脑,操作简单,容量大,是替代进口产品的最佳选择。

9. High Temp. Multi Rope Soft Dyeing Machine:

Product Description & General information:

This machine is designed in accordance with overflow machine. The fabric is fully mixed with high temperature circulation dyeing solution for a long time and transferred to the fabric storage tank. The profile is L-type which effectively reduces height between the lifting roller and fabric, reduce the length of the fabric in the air, and reduce the fabric’s stress, the fabric stays long time in solution during the dyeing process. This technique enhances the coloring and even dyeing of the fabric, shorten dyeing time and reduce friction between fabric and dyeing machine. This makes sure the fabric in a soft nature.

本机是按照溢流机设计的。织物与高温循环染色溶液充分混合很长时间并转移到织物储罐中。型材为L型,有效降低了提升辊与织物之间的高度,减少了织物在空气中的长度,减少了织物的应力,织物在染色过程中长时间保持溶液状态。 该技术增强了织物的着色和均匀染色,缩短了染色时间并减少了织物与染色机之间的摩擦。 这确保了织物的柔软性。

Technical parameter:

Liquor ratio: 1:6~7

Maximum velocity of the fabric: 200~400m/min depends on different machine type

Maximum working temperature: 140ºC

Maximum working pressure: 0.38Mpa

Cooling rate: 3⁰C/min in average within the range of 130⁰C~100⁰C, 2⁰C/ min in average within the range of 100⁰C~85⁰C (the cooling water is at 0.3Mpa, 25⁰C)

Heating rate: 5⁰C/min in average within the range of 25⁰C~100⁰C, 2.5⁰C/ min in average within the range of 100⁰C~130⁰C (the average pressure of dry saturated steam is 0.7Mpa).

Capacity: 250KG-1500KG

10. Rotary Refining Pre-Shrinking Crepe Washing & Dyeing Machine for Textile

Features: This machine is wide scope application, low liquid ratio and precisely designed parts.

特征: 该机适用范围广,液比低,精确设计。

Material: Silk Fabric

材质:真丝面料

11. Soft Flow and Jet Flow High temperature Dyeing Machine

Product Description: GYFX-F Soft flow and jet flow high tempreture dyeing machinery.The chamber is divided into three layers-upper layer, slide section layer and bottom layer. This state of the art design of the chamber combines the excellent low LR of the round shape dyeing machines and the wide suitability of the L shape dyeing machines but not the disadvantages of limited suitability and large LR of the round shape and L-shape dyeing machine respectively.

产品描述:GYFX-F软流和射流高温染色机该腔室分为三层 – 层,滑动部分层和底层。这种先进的腔室设计结合了圆形染色机的优异低LR和L形型大型机的广泛适用性而不是 形和L形染色机的适用性有限,LR大的缺点

TEXTILE DYEING MACHINERY

1. Environmental Liquid Dyeing Machine

Product Description:

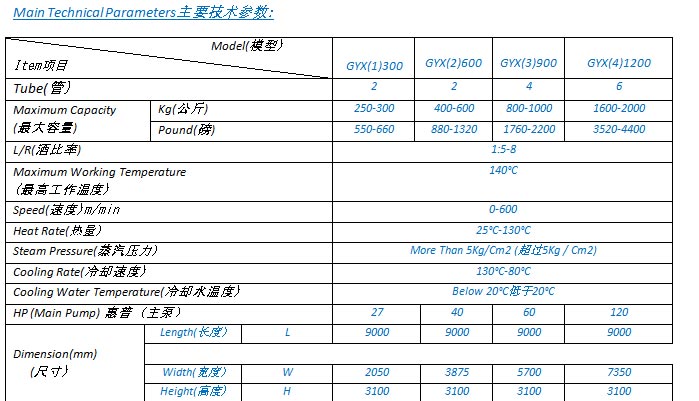

GYX series of environmental liquid dyeing machine-The latest developed dyeing machine Jet flow system, Wide applications both for woven and knitted fabrics such as Nylon, Polyester, Rayon, Suede or blended

产品描述:

GYX系列环保液体染色机最新开发的染色机喷射流动系统,广泛应用于尼龙,涤纶,人造丝,麂皮或混纺等机织和针织面料

Features:

1. Single head twin dyeing chamber designing Fabric dyed color difference problem will be much improved in this designing, the circulation time can be uniform. Small loading capacity and high Liquor Ratio Problem can be solved in GYX machine.

2.Low Machine Covered Area, High ProductionSingle Head, Twin dyeing chamber designing, Compare to traditional designing, Less area required and High Production

3. Wide Application for dyeing various type of fabrics (For light fabric, adjust less loading capacity is necessary for corresponding the cycle time 3 minutes limits)

4. Low tension designing Step 1 Fabrics moving forward till the Water-Fabric Separate Device, In this period Fabric water contained in minimum percentage so Fabric Weight will be much lighter then in the immersed conditionStep2 the driving reel pull up the fabric and send to main Jet Flow nozzle system In the minimum distance , Under this principle, fabrics will run in high Speed, Low-tension condition.

5. Superior fabric Dyeing quality and Processed hand feeling

6. Excellent fabric running condition and stability, less chance of fabric entanglement

特征:

1.单头双染色室设计在此设计中,织物染色差异问题将得到很大改善,循环时间可以均匀。小容量和高液位比问题可以在GYX机器中解决。

2.低机器覆盖面积,高产量单头,双染色室设计,与传统设计相比,所需面积更小,产量更高3.适用于各种类型织物的染色 对于轻型织物,需要调整较小的装载量,以对应循环时间3分钟的限制)

4.低张力设计步骤1织物向前移动直至水织物分离装置,在此期间织物水含量最小百分比因此织物重量将比浸入状态轻得多。步骤2驱动卷筒拉起织物并送至主喷射流喷嘴系统在最小距离,根据这个原则,织物将在高速,低张力条件下运行.

5.优质面料染色质量和加工手感

6.优异的织物运行状态和稳定性,减少织物缠结的机会

Optional Equipments (选配设备):

(i). Temperature Control System (温度控制系统)

(ii).Fabric Length Measuring Device (织物长度测量装置)

(iii). Steam Detector(蒸汽探测器)

(iv).Traverse Device for Fabrc Drawing(织物拉伸用横动装置)

(V). Automatic Chemical & Dyestuff Supplier(自动化学和染料供应商)

(vi).Centralized(集中)

(vii).Monitoring System(监视系统)

(viii). Inverter Control System in Main Pump(主泵逆变器控制系统)

(ix). The Higher or More Functional Controller(更高或更多功能的控制器)

2. GUR Series Uniform Automatic Textile Dyeing Machine for Cotton Fabric

Product Description:

A new generation of GUR series of multi-functional high-temperature dyeing machine is designed according to the idea- “low cost, high productivity, environment-friendly”. When the machine is designed, every link should be liked closely and every detail should meet the requirements. Besides when it comes to dyeing and processing different fabrics like all kinds of natural, synthetic and blended, the machine can meet the requirements of these fabrics and the process of them, moreover, the machine can enhance the entire dyeing and finishing process for achieving full support which is efficient, energy-saving and environmental.

新

一代GUR系列多功能高温染色机按照“低成本,高生产率,环保”的理念设计。设计机器时,应密切关注每个环节,每个细节都应符合要求。此外,在各种天然,合成,混纺等不同面料的染色和加工方面,该机器可以满足这些面料及其工艺的要求,而且,机器可以提高整个染整工艺,实现全面 高效,节能

Product Characteristics产品特性

1. Environmental protection and water conservation .The minimum water ratio of the machine can as low as 1:4. Water consumption of per kg of fabric in the whole process of cotton fabric dyeing by reactive dyes as follows:

Light color: 28.2 L

Neutral color: 38.8 L

Deep color: 48.9 L

1. 环境保护和水资源保护机器的最低水比可以低至 1:4。 每公斤耗水量织物在整个棉织物的过程中活性染料染色如下:

浅色:28.2升

中性色:38.8升

深色:48.9升

2. Automation and time saving The Machine is equipping process of cotton fabric dyeing by reactive dyes a follows:

Light color: 252 min

Neutral color: 272 min

Deep color: 291 min

2.自动和省时该机配备了多个自动控制和智能清洗技术。 整个过程的时间用活性染料染色的棉织物如下:

浅色:252分钟

中性色:272分钟

深色:291分钟

3. The single maximum load of up to 300 kg, and 1 to 12 tube sampling, to meet the needs of different users, makes the production more flexible and efficient.

3.单个最大载荷可达300kg,1至12 管取样,以满足不同用户的需求,使生产更加灵活和

4.Automatic hair removal system (patented design)The machine can remove hair and filter them automatically without manual cleaning, which reduces the workload and saves time of process.

4. 自动脱毛系统(专利设计)该机器可以自动清除头发并过滤,无需手动清洁,从而减少了工作量并节省了加工时间

5. High-quality of dyeing The machine is applicable to a variety of materials and can overcome the shortcoming of GUR series of dyeing machine that when in a low water ratio, the high-density fabric is easy to crease. For example, 26S/1,20S/1 cotton with long-fiber or ultra-fine fiber with spandex blended fabrics may have a dyeing defect when dyed by sensitive color, such as gray, brown, emerald blue, et al. The exclusive two-way uniform flow technology of the dyeing machine can fix this problem completely

6. 高品质的染色 该机适用于各种材料和 可以克服GUR系列染色的缺点 机器在低水比时高密度面料容易折皱。 例如,26S / 1,20S / 1棉 采用长纤维或超细纤维与氨纶混纺 织物在敏感染色时可能会有染色缺陷 颜色,如灰色. 翠绿色等. 独有的染色双向均匀流动技术 机器可以完全解决这个问题.

3. Industrial Fabric Dyeing Machine

Description:

1. The machine is suitable for wool, polyester, nylon, rayon, knitwear, etc. dyeing processing.

2. The liquid cylinder is using high quality contact and highly resistant to corrosion of the 202” stainless steel plate manufacturing, to ensure that no pollution fabric, durable.

3. Dyeing tank wall and paddle wheel are surface polishing treatment; ensure that the fabric is not compromised.

4. According to different fabric dyeing requirements and heavy, but through without for electrical devices to any high speed rotating speed paddle.

5. Dyeing process all by starting to stop all by electric box button operation, the dyeing time can be by the time the automatic control, dyeing time can be adjusted according to the different needs in advance.

6. Through the power of the positive and negative turn to be automatic controller, make dyeing tank paddle wheel fall within the rotation, the liquid flow changes and the fabric,so as to improve the dyeing effect.

7. According to different dyeing process requirements, in the crock bottom installation direct or indirect steam pipes to heat, heat preservation effect.

描述:

1.该机适用于羊毛,涤纶,尼龙,人造丝,针织品等。染色加工。

2.液压缸采用优质接触和高耐腐蚀的202”不锈钢板制造,确保无污染面料,经久耐用。

3.染色罐壁和桨轮均经过表面抛光处理,确保织物不受损害。

4.根据不同的织物染色要求和重型,但通过无需电气设备的任何高速旋转速度桨。

5.染色过程均由电箱按钮操作开始全部停止,染色时间可由自动控制,染色时间可根据不同需要提前调整。

6.通过正反转动力自动控制器,使染色槽叶轮内旋转,液体流动变化和织物,从而提高染色效果。

7.根据不同的染色工艺要求,在缸底安装直接或间接蒸汽管道,以加热,保温效果。