Single Stage Compressor

OPEN TYPE SINGLE STAGE SCREW COMPRESSOR OF AMMONIA(R717) REFRIGERATION

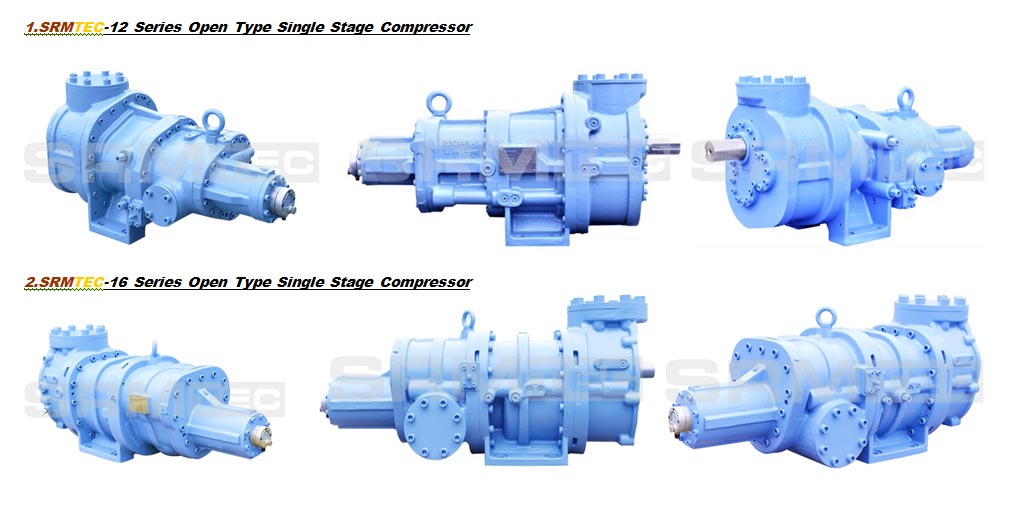

Single Stage Different Series Compressor Picture:

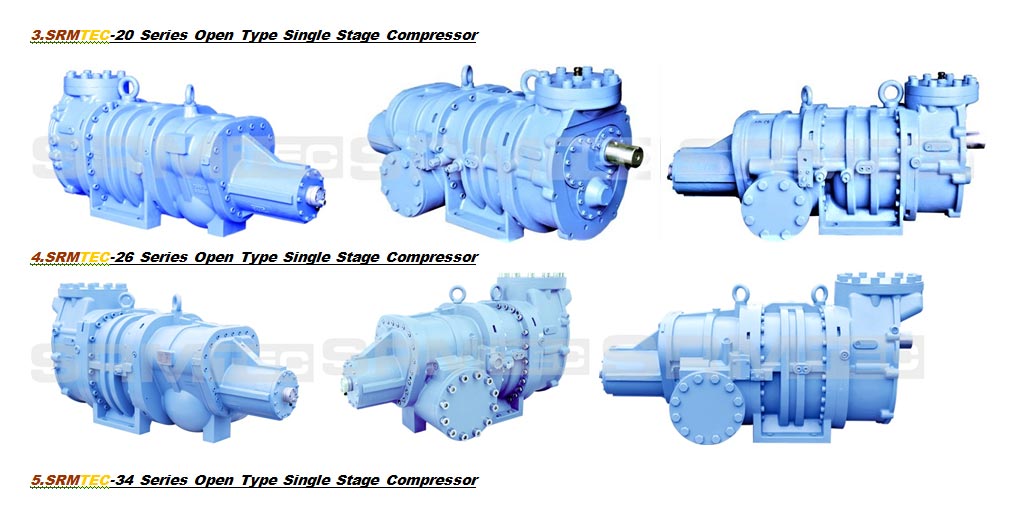

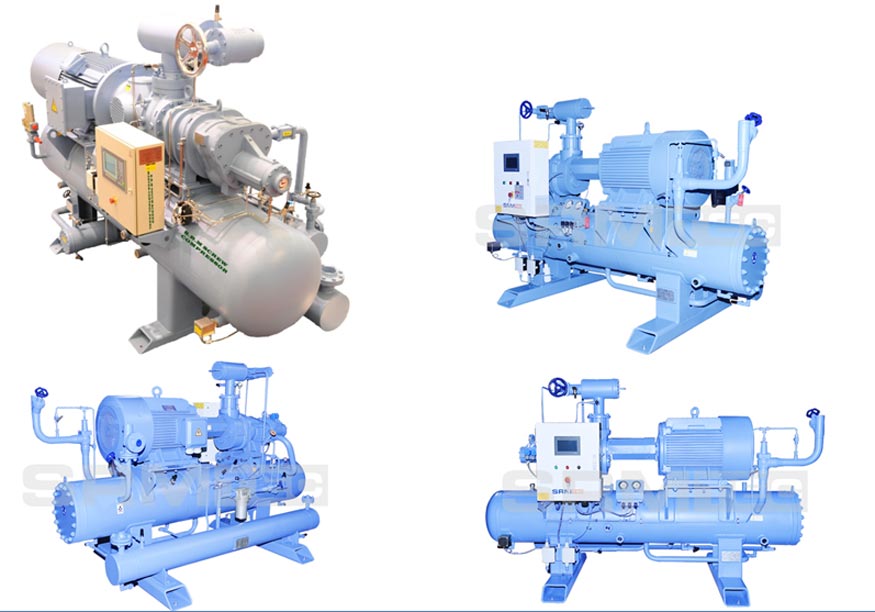

Complete Picture of Single Stage Compressor:

Complete Picture of Single Stage Compressor:

Product Description

SRM Open-type Single- stage Screw Compressors include 6 series totaling 19 models. Displacement 265- 10850m3/h(2960RPM),discharge temperature – 45°C to +20°C , applicable for the natural and environment-friendly refrigerants such as R717, R404A, R507A, etc. Step less (10%- 100%) capacity control: intelligent controller with accurate selection and rapid response to ensure to operate in high EER under different working conditions. The designed obliquity >30°, which is also applicable to the refrigeration systems on the marine units.

Features of SRM open-type single-stage screw compressor:

●“I”type patented profile, best lobe ratio of 5+7, high efficiency.

●Rotor is made of high- quality forged steel with micron- machining accuracy, rendering excellent overall mechanical properties, high strength, high wear resistance, and long durability.

●The housing is made of high- strength ductile iron, working pressure 2.8Mpa.

●Innovative shaft seal. The wear- resistant sealing surface is made of silicon carbide, rendering high reliability.

●High- precision and wear- resistant rolling bearings with the designed life of 100 thousand hours.

●Vi control function ensures high efficiency operation under various working conditions.

●Step less capacity control (10- 100%) with the proprietary technology of explosion- proof cylinder of the capacity control.

●Integrated oil circuit: easy installation and low failure rate.

Merits of open-type single-stage inverter screw compressor unit:

● SRM high- efficiency screw compressor: higher COP than the same type of compressor units.

● Open asynchronous motor with high efficiency and low noise; the permanent magnet synchronous variable frequency motor is also available for selection.

● Differential- pressure oil supply system with a small oil pump as pre- lubrication: energy- saving and reliable.

● Economizer installed: make the high pressure liquid from the condenser sub cooled, thus improve COP of the system.

● Fully automatic one- key start- up; real- time analysis and monitoring of the operation status; saving and keeping of the historical data, remotely control.

● Automatic capacity control make the unit run with high efficiency under various working conditions.

● The preventive safety and protection system: unmanned but safe and reliable.

●All the components are from well-known manufacturers: high reliability and guaranteed quality.

● Each unit is tested and checked for its full performance to ensure the quality.

Controls

Compressor Starter:

**For Highest safety, performance and Easiest operating SRM / MYCOM Ammonia Screw Compressor the unit is consist of following Technical facilities .Very easy Auto-Couple Step-Down Starter which is better than Star-Delta Starter. Maintenance is easy & low cost, power saving even an ordinary Electrician can easily work on this starter.

Manufacturing Process & Quality Control:

In manufacturing process totally followed S.R.M TEC Technical Guidance, Design, and Component. Compressor Rollar bearing also SKF of SWEDEN. Fully Automatic control System also established and implement by SCHNEIDER-FRANCE, SIMENS-GERMANY & OMRON-JAPAN. Even according to Technical design and Guideline Rotor is Cutting and after cutting Rotor It is sent to S.R.M TEC SWEDEN for Accuracy, quality test and also for Glue Nitride Treatment. This way after all accuracy, precision and quality checking then we go in assembling. So to maintain quality need to do these processes and these processes are very effectively.

PARENTS MANUFACTURER: SRMTEC SWEDEN

SUBSIDIARY 100% OWNED BY: SNOWMAN CHINA

MANUFACTURING DESIGN AND TECHNOLOGY:SRMTEC SWEDEN

INVESTMENT AND MANUFACTURING BY: SNOWMAN CHINA

S.R.M TEC SWEDIST TOP MANAGEMENT PEOPLE WITH CHINESE MANUFACTURING PARTNER:

S.R.M TEC SEWDIST TOP MANAGEMENT PEOPLE WITH THEIR CHINESE PARTNER:

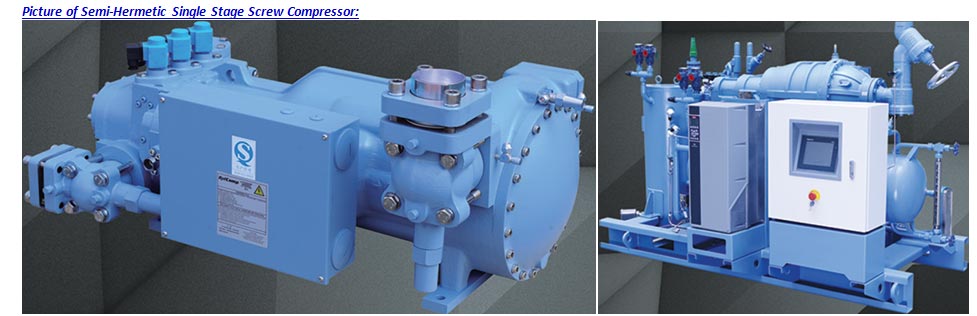

Semi-hermetic Single-stage Screw Compressor

Product Description

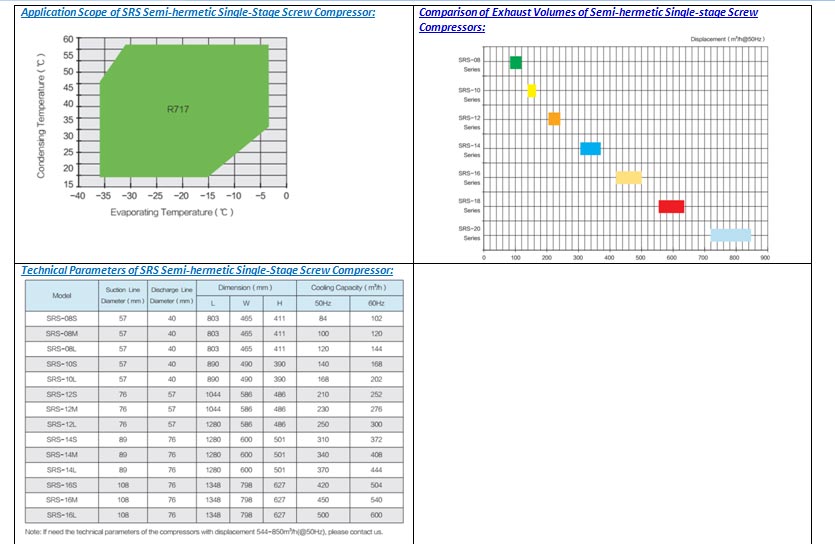

SRS Semi-hermetic Single- stage Screw Compressors include 20 models, displacement 85- 850m3/h (50Hz), designed pressure 2.8Mpa,applicable for R717. Compact structure, easy maintenance, low vibration and noise, zero leak of refrigerant. The compressor is packaged with the permanent magnet synchronous variable frequency motor, which regulates the rotor speed to improve the operation efficiency of the compressor.

Features of SRS semi-hermetic single-stage screw compressor:

●“I”type patented profile, best lobe ratio of 5+7, high efficiency.

●Compact structure: filter, shut- off valve, temperature sensor, and oil flow switch are integrated;

●Tailor- made materials are specifically used for NH3.

●Packaged with the permanent magnet synchronous variable frequency motor, which regulates the rotor speed to improve the operation efficiency of the compressor.

●Vi step less control: manual or automatic.

●Capacity control: step or step less.

●Embedded 100μm suction filter: remove the impurities of the refrigerant and protect the motor.

●High- efficiency cooling is achieved through refrigerant circulation to ensure the stable and efficient operation of the motor.

Semi-hermetic Single-stage Screw Compressor

CONTROLS

Manufacturing Process & Quality Control

In manufacturing process totally followed S.R.M TEC Technical Guidance, Design, and Component. Compressor Rollar Bearing also SKF of SWEDEN. Fully Automatic control System

also established and implement by SCHNEIDER-FRANCE, SIMENS-GERMANY & OMRON-JAPAN. Even according to Technical design and Guideline Rotor is Cutting and after

cutting Rotor It is sent to S.R.M TEC SWEDEN for Accuracy, quality test and also for Glue Nitride Treatment. This way after all accuracy, precision and quality checking then we go in

assembling. So to maintain quality need to do these process and these process are very effectively.

PARENTS MANUFACTURER: SRMTEC SWEDEN

SUBSIDIARY 100% OWNED BY: SNOWMAN CHINA

MANUFACTURING DESIGN AND TECHNOLOGY:SRMTEC SWEDEN

INVESTMENT AND MANUFACTURING BY: SNOWMAN CHINA