Textile Spinning and Weaving Machinery

BLOW ROOM

1. Reciprocating Bale Plucker for Cotton spinning production line:

Description:

The machine FA017 series is the carriage reciprocating type automatic bale plucker, applicable to raw cotton of various grades and man made fibers below 76mm.This machine

is also the first process of the combined opening and scutching machine or the blow room unit, and its intermittent dropping plucking beater can reciprocate with the revolving

tower and the carriage, pluck bales in sequence, and then convey materials to the next machine through transport fan and pipes

Main Features:

Bales can be placed in two sides. The machine can pluck 1 to 3 group bale with different height and Meet the demand for kinds of yarn at the same time. Tower can revolve 180. It is designed with two plucking rollers and two detecting rollers. With different working width of milling there are 1723 plucking knives and 102,138 tips on each plucking

Machine Picture:

| Parameters | Beater Width1720(Special) | Beater Width 2300 (Normal) | |

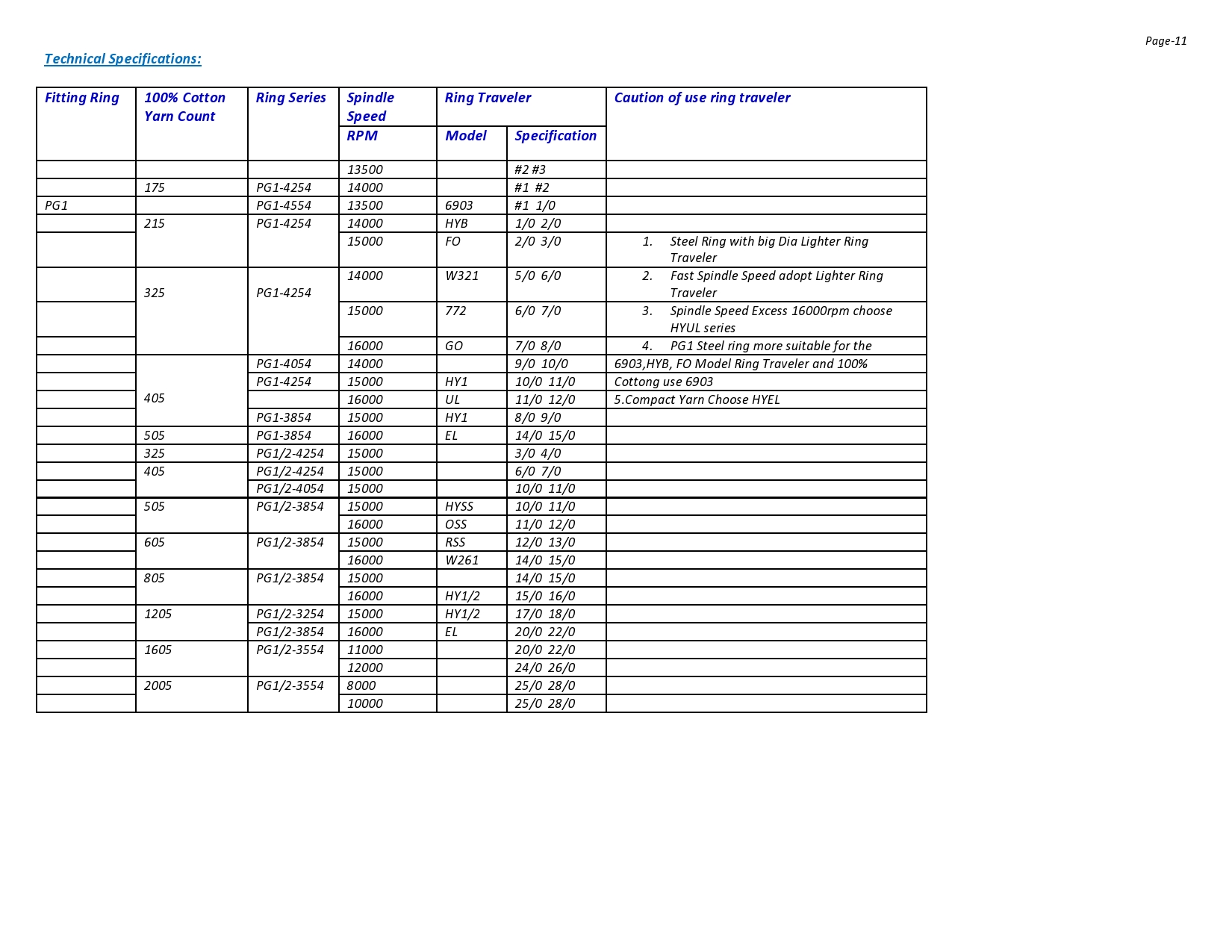

| Production | 1000Kg/h | 1500Kg/h | |

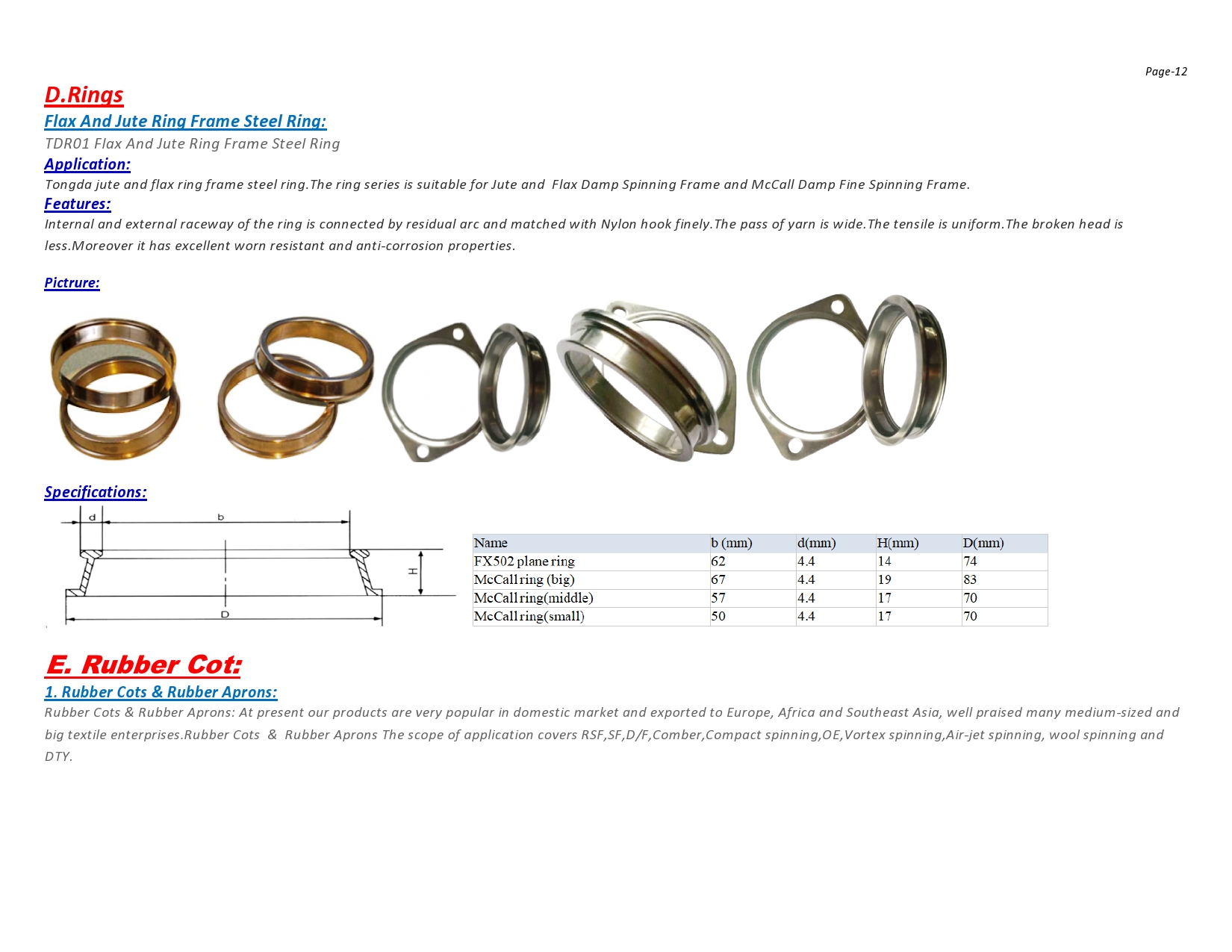

| Basic Pile Weight | 6000Kg | 7500Kg | |

| Length of floor Space | Basic Type 22.03m(8 section of Air Ducts) can be increased or decreased by 2.5 mxn | ||

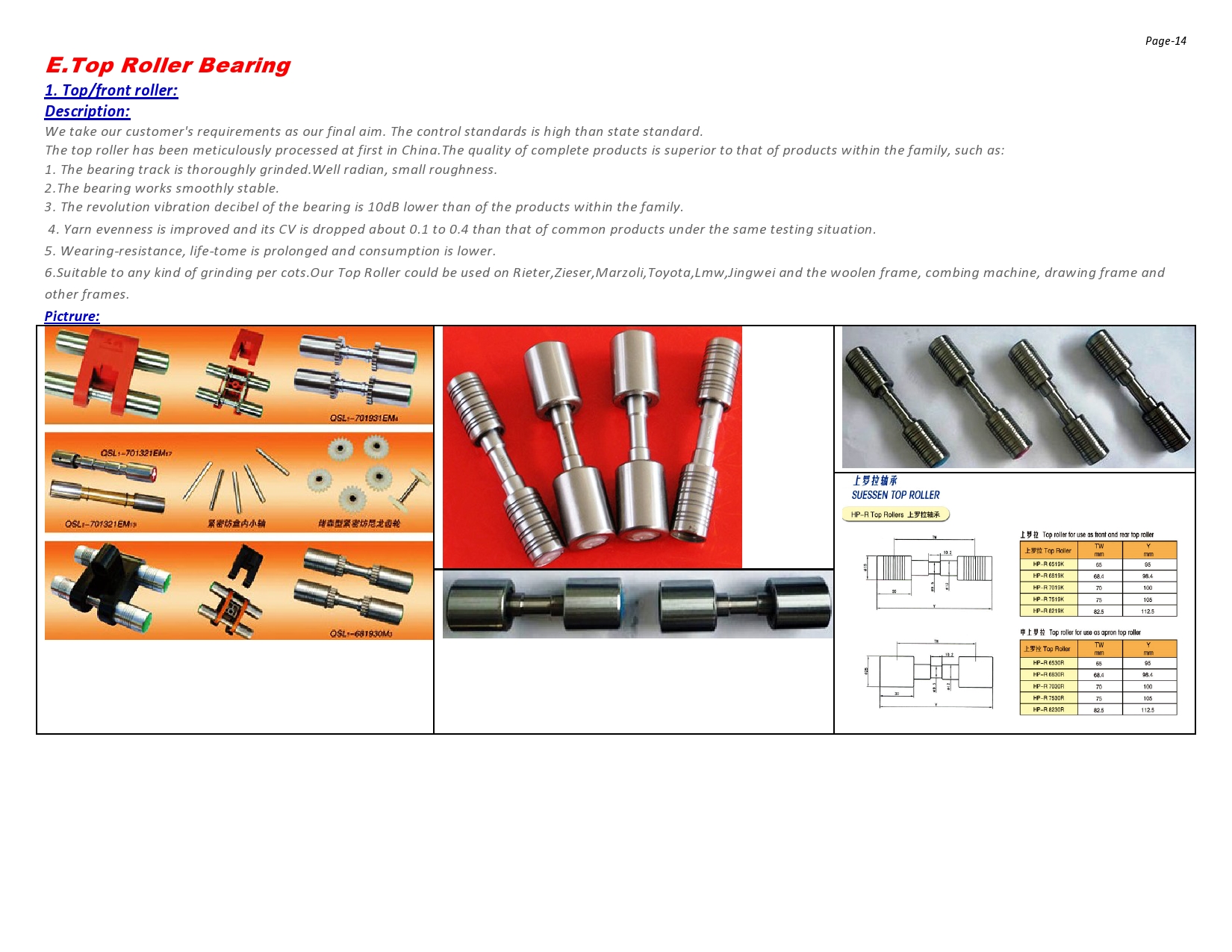

| Balse Arrangement Length | Basic Type 15.9m(8 section of Air Ducts) can be increased or decreased by 2.5 mxn | ||

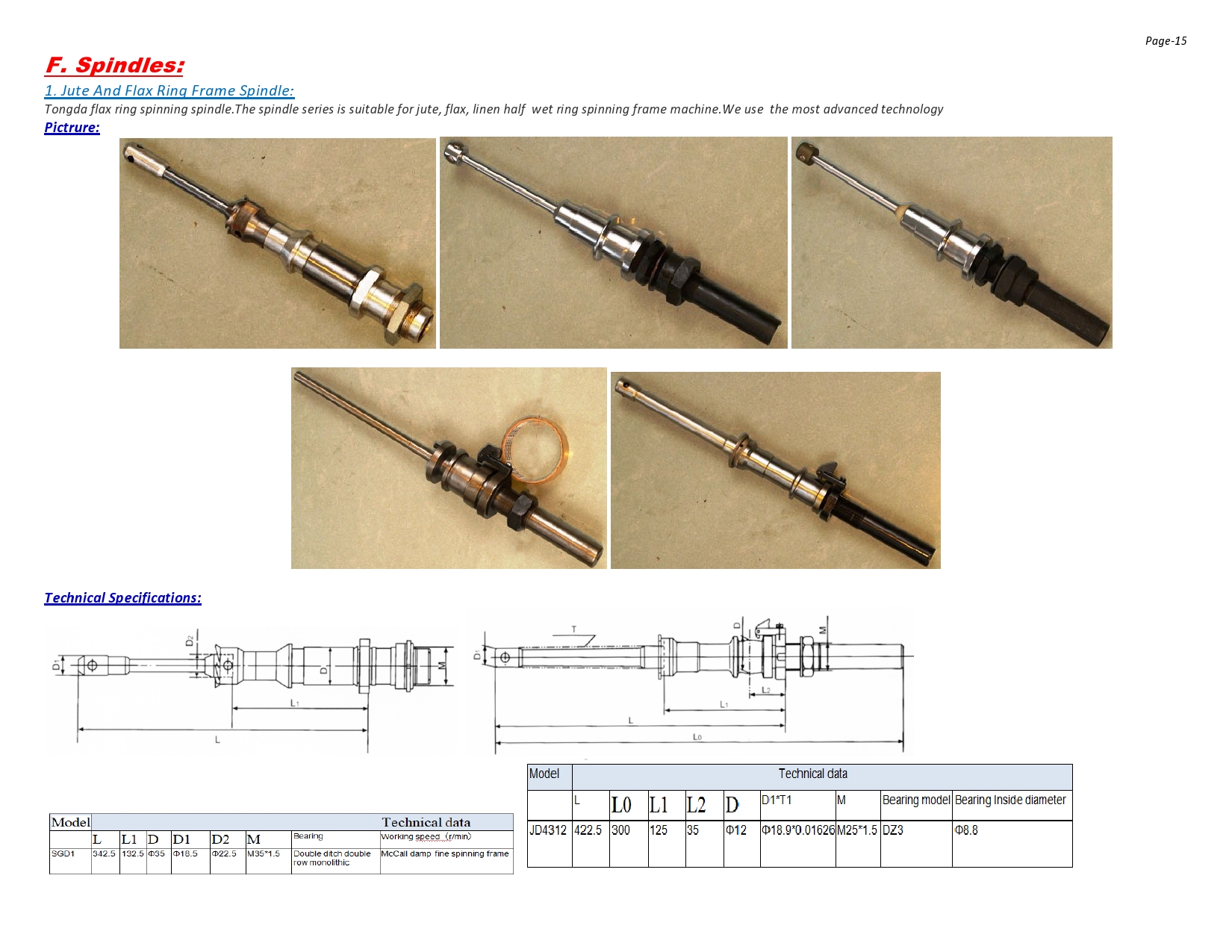

| Intermittent Dropping of Beater | 0.5~10mm/time frequency Control usually 1~3mm/time | ||

| Calendar Roller Dia | ɸ130mm both sides, Middle ɸ116mm | ||

| Carriage Reciprocating Speed | 16.4m/min(Max) Generally 10m/min | ||

| Installed Power | 8.6KW | 10.6KW | |

| Overall Size | 22030*5212*3082 | 22030*6648*3082 | |

| Net Weight | 6000 | 6500 | |

2. FT215B LITTLE DUST SEPARATOR:

Description:

FT215B Little dust separator mainly used in the frontier of the blow room & card system. It can separate little dust and make air current balance. This product is usually used before Roller Cleaner. FT215B little dust separator main features:

Simply structure, no running and electrical equipment parts; maintain conveniently; the exhaust capacity of dust outlet is adjustable; Dust outlet must be connected with dust filtration system

Machine Picture:

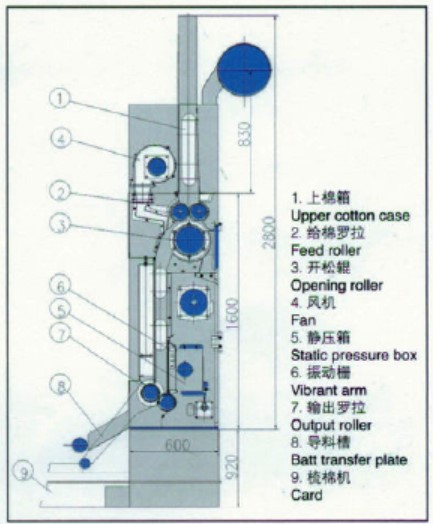

- FA171 CHUTE FEEDER:

Description of FA171 CHUTE FEEDER:

This machine is a connecting unit between cards and blow room whose function is to make fiber (after being opened and mixed) feed to card in even but ensure continuous and even cotton supply for card.

MAIN FEATURES:

(i). Good open effection, low fiber damage.

(ii). Two feed rollers feed materials to prevent from warping.

(Iii). The feed roller controlled by by inverter. It is mounted with protection unit.

(iv).The space between feed roller and open roller is adjustable.

(v).The vibrant favorable for forming even uniformity fiber batt.

(vi). The output roller draft for improving sliver eveness is improved.

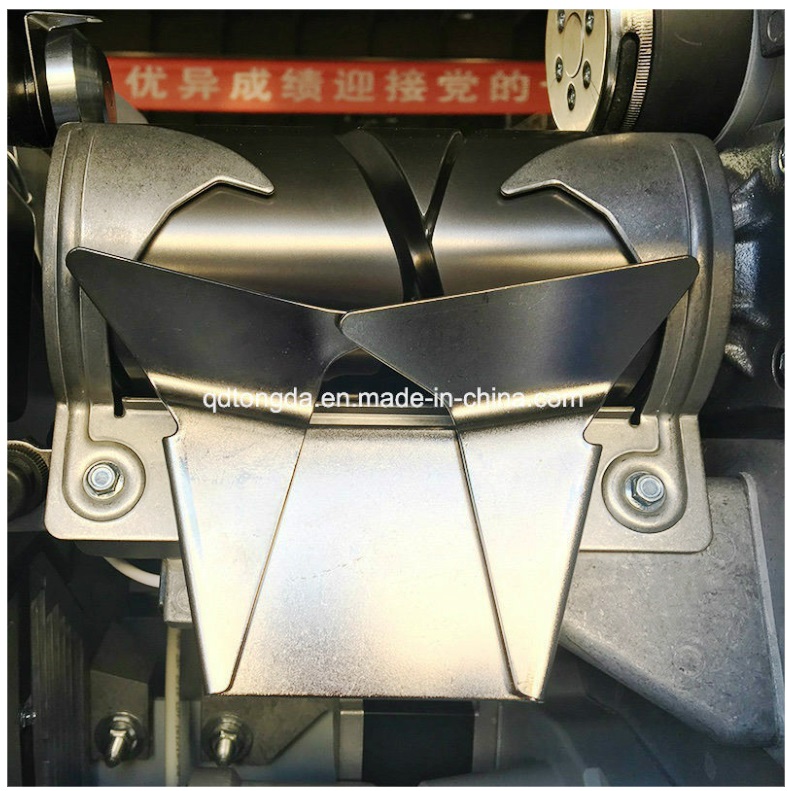

Machine Picture:

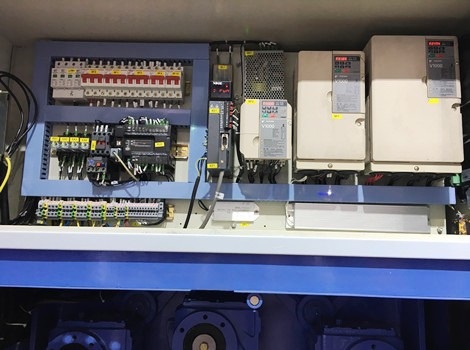

ELECTRICAL CONTROLL:

FA171 chute adopts imported inverter to control each motors. It has electrical cabinet; all electrical elements are controlled by imported PLC. No need of start or stop independently.

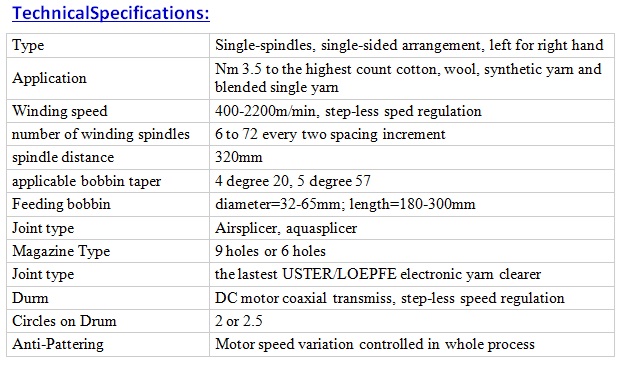

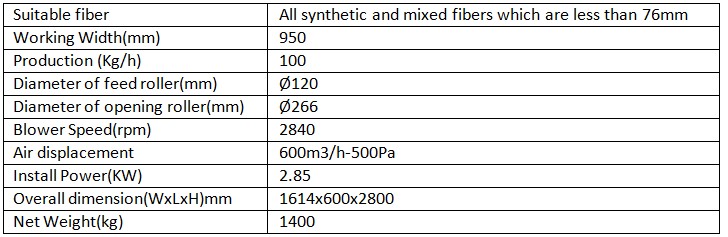

TECHNICAL SECIFICATIONS

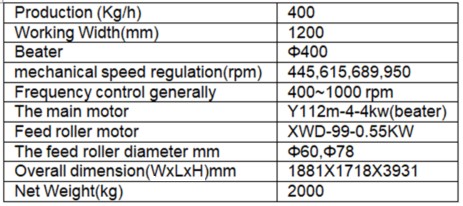

4. FA117 SERIES FINE OPENERS:

Application:

The machine is a kind of new and high-efficiency fine opener, which chute feeder for the purpose of further trash extraction and fan, raw materials are fed through inlet to the

Stepped passage, then transferred to the feed roller, beaters and mote knife Components through the dust cage and the flat roller, and finally conveyed to the next process by air

Currents after being after being after being opened and cleaned

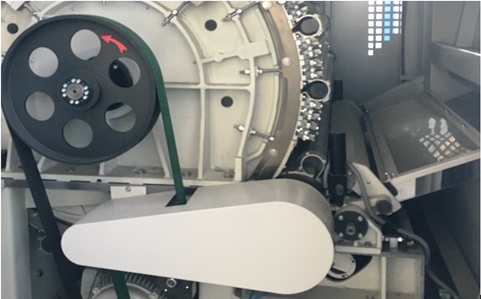

Machine Picture:

Main Technical Parameters:

CARDING

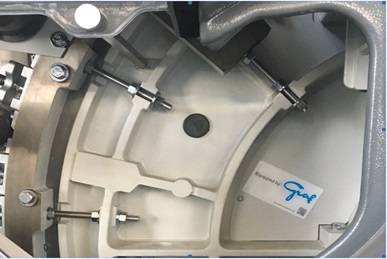

1. FA204C Good Cost Performance Carding Machine in Spinning Production Line:

FA204 Carding machine with modular design Licher-in section adopts single licker-in and three -licker-in modular design and two noel area can be easily adjusted outside machine.Mote knife under licker-in and clean unit can be used for adjusting noel quantity to reduce fiber loss. Tandem stationery flat, web cleaner, Al-alloy sheet can be configurated and fit in different group according to material, featured by flexible mantling and dismantling, good trash excluding efficiency.

Basic Information & Technical Specification

Model No. | TD204C means FA204C |

Condition | New |

Deliver Speed | 20-220m/min |

Output | 25-80Kg/h |

Layer Weight | 400-800G/M |

Sliver Weight/Count | 3.6-6.5G/M |

Width | 1020mm |

Working Width | 1000mm |

Total Draft | 68.7-152.8 |

Taker-In Diameter | 250mm |

Taker –In Speed | 823; 983;1039rpm |

Cylinder Speed | 1289mm |

Total Power | 6.88KW |

Air amount for Continuous Dust Suction | 3500m3/h, Air Pressure 850-950 Pa |

Compressed Air | 0.4-0.7Mpa |

Air Consumption | 0.01M3/h, if the machine is equipped with closed loop autoleveller,the air consumption is 0.03m3/h |

Floor Space | 3132*1974mm(L*W) (Without Coiler) |

Trademark | Tongda |

Machine net Weight | 5500Kg |

Warranty | 12 Months |

Customized | Customized |

Origin | China |

Transport Package | Standard Export Package |

HS Code | 8445111300 |

2. FA206B High Speed Carding Machine:

2. FA206B High Speed Carding Machine:

Basic Information & Technical Specification:

Model No. | FA206B |

Condition | New |

Deliver Speed | 20-220m/min |

Output | Up to 80Kg/h |

Layer Weight/Feed Weight | 300-1000G/M |

Sliver Weight/Count | 3.6-6.5G/M |

Width | 1020mm |

Working Width | 1000/1250mm |

Total Draft | 60-300 |

Feed Roller Diameter | 100mm |

Doffer Dia | 706mm |

Doffer Speed | 4-65 R/Min |

Licker –In Speed | 180 |

Cylinder Speed | 1289 mm |

Total Power | 6.88KW |

Air Amount for Continuous Dust Suction | 3500m3/h , Air Pressure 850-950 Pa |

Compressed Air | 0.4-0.7MPa |

Air Consumption | 0.01M3/h, if the machine is equipped with closed loop autoleveller,the air consumption is 0.03m3/h |

Floor Space | 3132*1974mm(L*W) (Without Coiler) |

Trademark | Tongda |

Machine net Weight | 5500Kg |

Origin | China |

Type | Spinning Production Line |

Automation | Automation |

Spinning Method | Ring Spinning |

Processed Material | Cotton |

Certification | ISO9001:2000 |

Warranty | 12 Months |

Customized | Customized |

Transport Package | Standard Export Package |

3. High Output FA236 Carding Machine for Spinning Production Line:

Basic Information & Technical Specifications:

Model No. | FA236 | : | Taker-In Diameter | 250mm | |

Condition | New | : | Taker –In Speed | 823; 983;1039rpm | |

Deliver Speed | 20-220m/min | : | Cylinder Speed | 1289mm | |

Output | 25- 80Kg/h | : | Total Power | 6.88KW | |

Layer Weight/Feed Weight | 400-800G/M | : | Doffer Speed | 4-65 R/Min | |

Sliver Weight/Count | 3.6-6.5G/M | : | Air Amount for Continuous Dust Suction | 3500m3/h , Air Pressure 850-950 Pa | |

Width | 1020mm | : | Compressed Air | 0.4-0.7MPa | |

Working Width | 1000mm | : | Air Consumption | 0.01M3/h, if the machine is equipped with closed loop autoleveller,the air consumption is 0.03m3/h | |

Total Draft | 68.7-152.8 |

| Trademark | Tongda | |

Floor Space | 3132*1974mm(L*W) (Without Coiler) |

| Automation | Automation | |

Machine net Weight | 5500Kg |

| Processed Material | Cotton | |

Origin | China |

| Certification | ISO9001:2000 | |

Type | Spinning Production Line |

| Warranty | 12 Months | |

Automation | Automation |

| Customized | Customized | |

Spinning Method | Ring Spinning |

| Transport Package | Standard Export Package | |

Advantages: |

| ||||

(i). intellgence control |

| ||||

(ii). High Quality and High Efficiency |

| ||||

(iii).Easy Peroration and Maintenance |

| ||||

DRAWING FRAME

1. Tongda FA316A High Speed Drawing Frame in Spinning Production Line:

Machinery Feature :

FA316 High Speed Draw Frame is used for yarn spinning

- The machine is suitable for fiber variety and high output speed.

- Adopt high quality four- up and down guide roller. pressure stick style double- curve drafting structure. The sliver quality is good and stay

3.Can choice the frequency converter to dominate steeples timing turning round at an average speed favorable to the sliver quality.

- The automatic can changer selected by customers. Can decrease the labor intensity of workers and improve work efficiency.

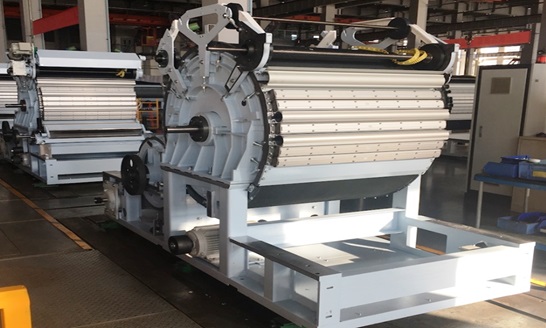

Machine Picture:

Basic Information & Technical Specifications:

Model No. | FA316A |

Condition | New |

Delivery Number | 2 holes |

Maximum Output Speed | 600m/min |

Total Drafting multiple | 5-14 times |

Drafting Style | 5 over 4with pressure bar |

Feeding Sliver Number | 6-8 pcs |

Suitable Fiber length | 15-76mm |

Input can dimension | Φ400, Φ500, Φ600, Φ800, Φ900, Φ1000, |

Can Height | 900,1100,1200mm |

Output can dimension | Φ350, Φ400, Φ450, Φ500, Φ600 |

Can Height | 900,1100mm |

Main Frame OAD | 2490x1000x2110mm |

Weight | 2400Kg |

Motor Power | 5.5KW |

Trademark | Tongda |

Certification | ISO9001:2000 |

Warranty | 12 months |

Customized | Customized |

Origin | China |

Transport Package | Standard Export Package |

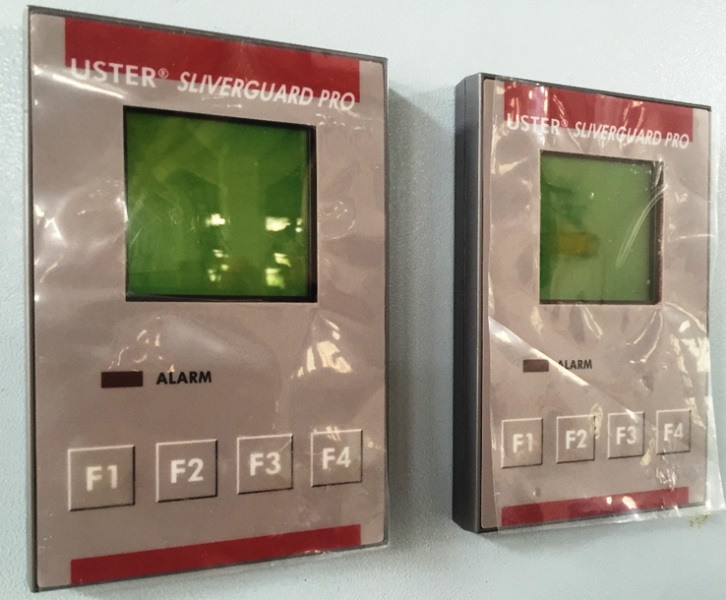

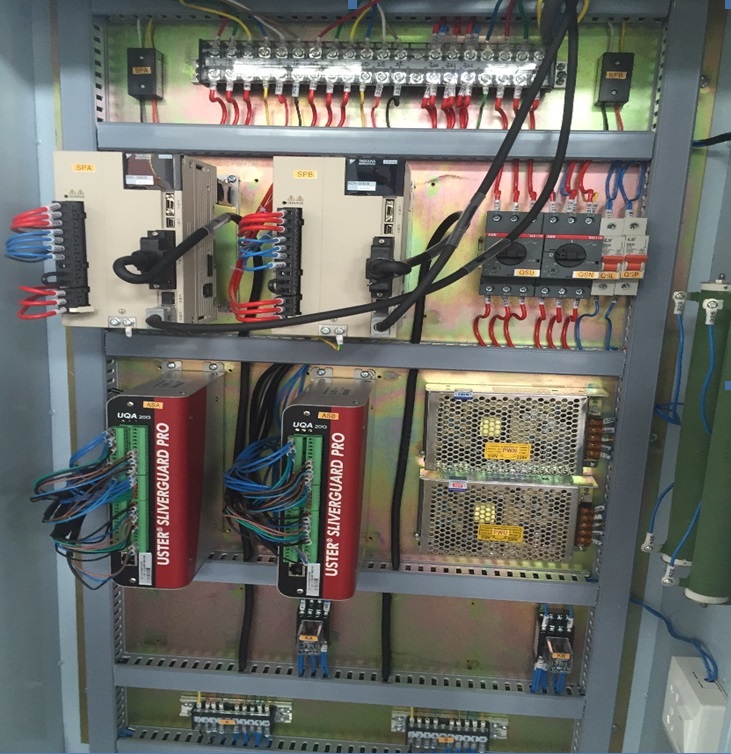

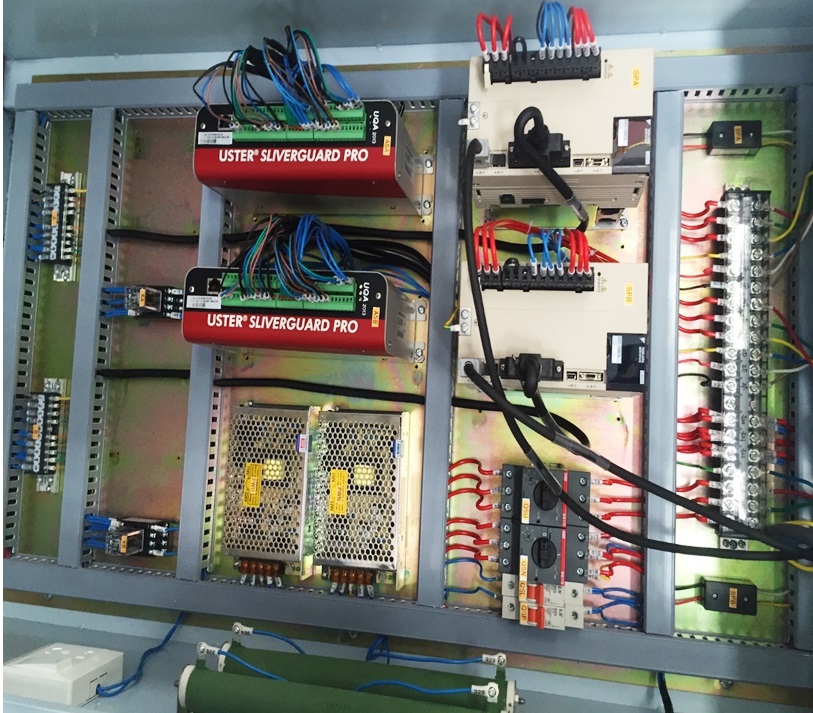

- FA318 High Speed Drawing Frame with Autoleveller:

Application:

This type machine can improve the silver quality, which adopts short Fiber auto leveler system (Uster, Switzerland) and five patents (concentration lubricating device,autoshaving

cotton device, draft driving mechanism).So this could control the drafting quality of sliver.FA318 adopts 5 over 4 with pressure bar drafting style, which can advance the uneven

condition of force. It is suitable for short fiber.

Machine Picture:

Basic Information & Technical Specifications:

Model No. | FA318A |

Condition | New |

Delivery Number | 2 holes |

Maximum Output Speed | 600m/min |

Total Drafting multiple | 5-14 times |

Drafting Style | 5 over 4with pressure bar |

Feeding Sliver Number | 6-8 pcs |

Suitable Fiber length | 15-76mm |

Input can dimension | Φ400, Φ500, Φ600, Φ800, Φ900, Φ1000, |

Can Height | 900,1100,1200mm |

Output can dimension | Φ350, Φ400, Φ450, Φ500, Φ600 |

Can Height | 900,1100mm |

Main Frame OAD | 2490x1000x2110mm |

Weight | 2400Kg |

Motor Power | 5.5KW |

Trademark | Tongda |

Certification | ISO9001:2000 |

Warranty | 12 months |

Customized | Customized |

Origin | China |

Transport Package | Standard Export Package |

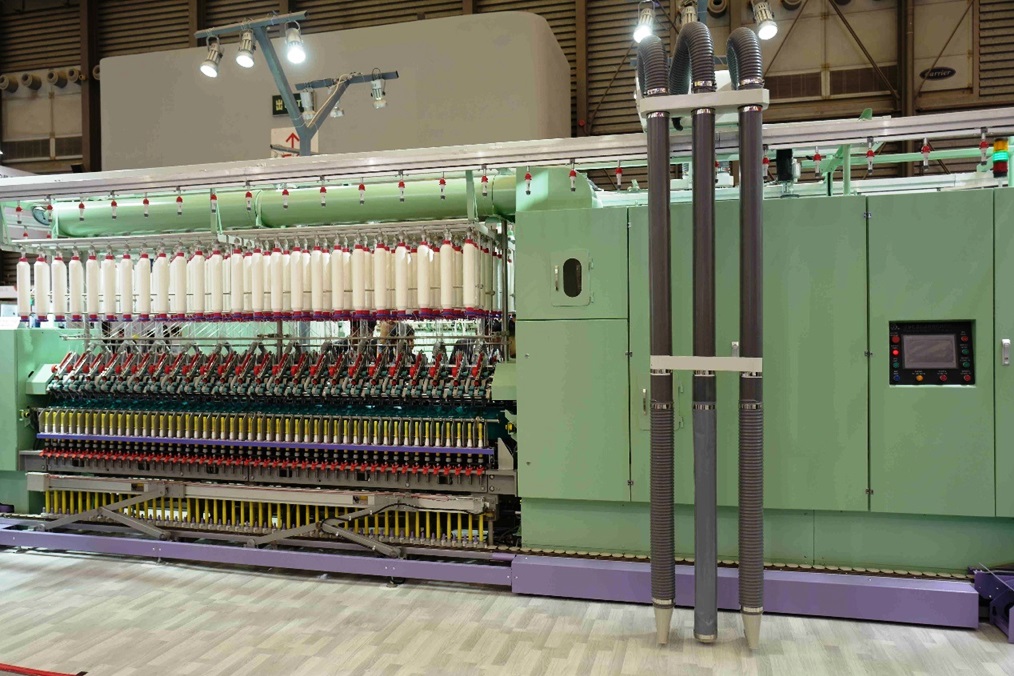

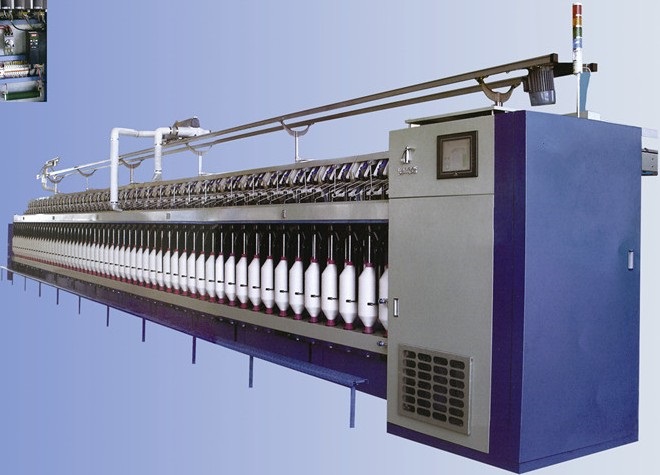

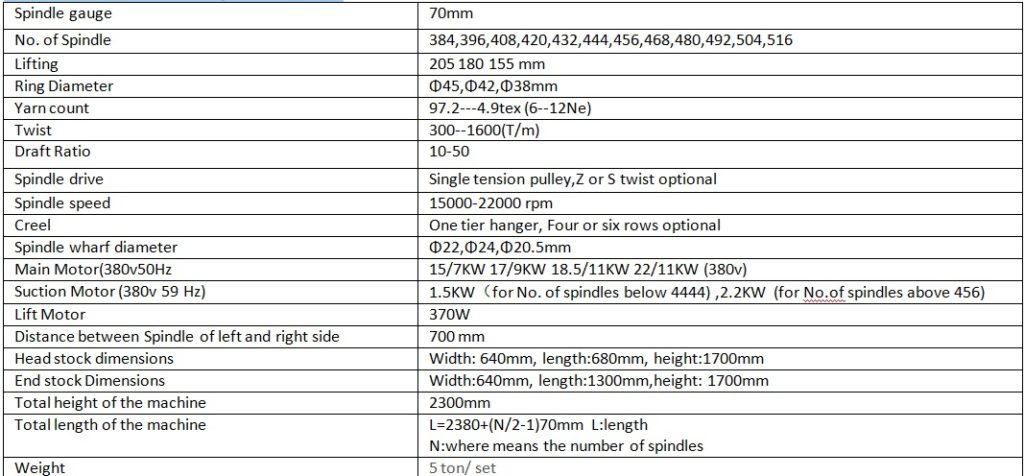

RING SPINNING FRAME

1.FA506 RING SPINNING MACHINE:

FA506 Ring Spinning frame series are made from the leading design proposal, advanced manufacturing methods and perfect special parts and components. They ensure high

quality yarn spring. The machine features convenient operation and easy to management due to its high automation.The machine is suitable to the processing of cotton, synthetic fibers or their blends.

FA506 Advantages:

(i).Advanced design

(ii).Simple operation

(iii).High running speed and high stability

(iv).Auto doffer time is within 3 minutes

(v).Guarantee better yarn quality

Machine Picture:

2.Ring Spinning Frame Auto-doffer (FA538):

Products introduction:

Model FA538 Ring Spinning Frame is a new machine designed and developed by feeding a single simplex roving, it is suitable for spinning cotton, synthetic fibers and their blends

to produce weaving and knitting yarns. The spinning processes can be set by means of man- machine dialogues through a Touch Screen Panel, and an interface or computer

network is ready for expanding.

High Speed,High efficiency and stability: CAPP technology improves the design of frame arrangement and ensures vibration free property and smoother running.The maximum medical speed for spindle is up to

25,000rov/min.The machine is suitable to the processing of cotton, synthetic fibers or their blends.

The Auto doffer is your best choice to decrease the cost and increase the output: The Auto- doffer’s structure combines the advantages from doffers in and out country. In and out swing and liftingof arms are controlled by servomotor and the lifting actions are accurate and reliable. Larger biston grippers have accurate and stable ejecting and lifting tube actions. After the doffer mounted, spinning cost is reduced largely and the connection of ring spinniging machines to winders can be obtained.

FA568 Advantages

(i).Advanced design

(ii).Simple operation

(iii).High running speed and high stability

(iv).Auto doffer time is within 3 minutes

(v).Guarantee better yarn quality

Machine Picture:

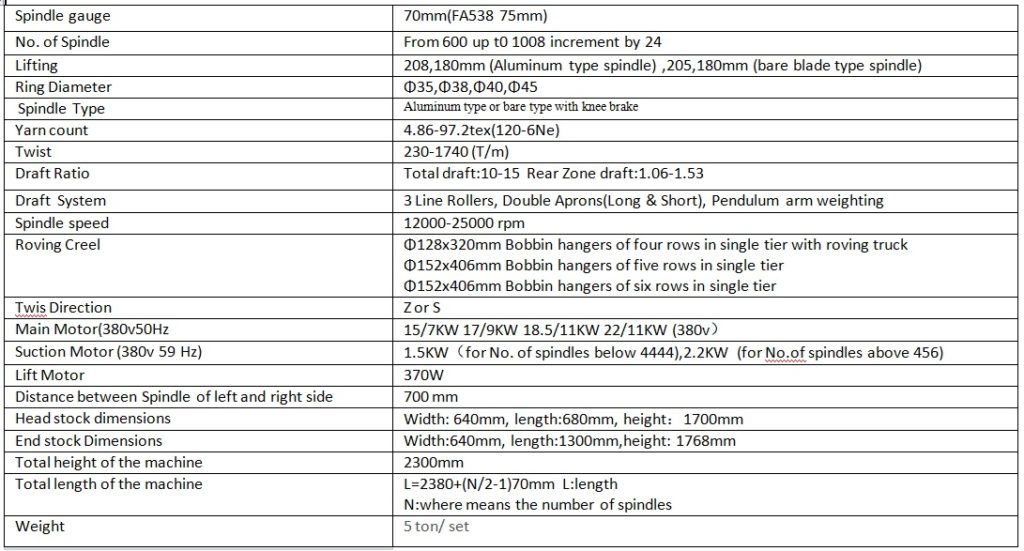

2.Ring Spinning Frame Auto-doffer (FA538):

FA538 Technical Data and Specifications:

- Auto Doffer Long Machine with 1200 Spindles Yarning Spinning Ring Frame:Model:FA568

Ring Spinning frame series are made from the leading design proposal,advanced manufacturing methods and perfect special parts and components. They ensure high quality yarn

spinning. The machine features are convenient operation and easy to management due to its high automation. It is suitable for spinning of cotton, synthetic fibers or their blends.

FA568 Advantages:

(i).Advanced design

(ii).Simple operation

(iii).High running speed and high stability

(iv).Auto doffer time is within 3 minutes

(v).Guarantee better yarn quality

Machine Picture:

3. Auto Doffer Long Machine with 1200 Spindles Yarning Spinning Ring Frame:Model:FA568

FA568 Technical Data and Specifications:

FLAX SPINNING FRAME

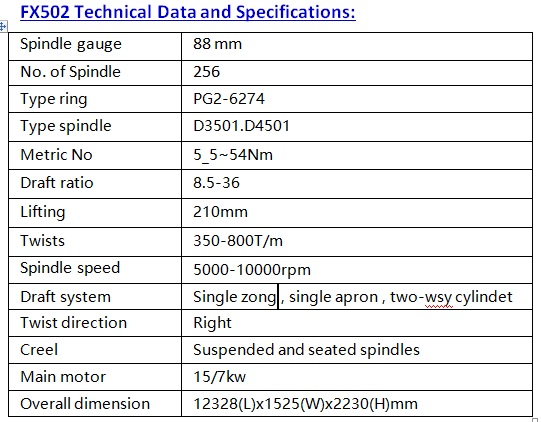

1. FX502 linen spinning machine:

Description of Machine:

FX502 linen spinning machine 3.0-1 World latest model FX502 Flax wet spinning frame, Have stepped over mechanical & Computerized Automatic Controlling , now enter into industry 3.0 version. Intelligent module and synchronized control to make sure that, the main shaft, drafting shaft, feeding roller shaft, and lifting shaft, 4 shaft are under control by computer mathematical modeling. It makes the ring frame to be intelligent module and synchronized controlled by gear motors. and complete the spinning process.The drafting shaft and feeding roller shafts all are using sealed ball bearings. it becomes the world advanced intelligent flax wet spinning machine.

Application:

- All of the technological parameter of the ring frame can be set freely by Touch screen no matter when machine running or when machine stop.

- The basic parameter of the roving sliver, yarn count and all the technological parameters will be generated automatically.

- The drafting shaft and feeding roller shafts all are using sealed ball bearings. so, the motion system will not need daily maintenance, it only need periodic service. It will bring down the cost of spinning.

- The motion system was composed by separate elements, The drafting shaft and feeding roller shafts all are using sealed ball bearings, the spindle tape material is aluminum,

To start/stop machine, changing technological parameters etc, will be freely touch screen. The vibration of the machine will be too much less.

- This machine will reduce the yarn breakage percentage will bring up the yarn quality.

- The spindle speed will be at least 7800 rpm, it can be reached up to10000 rpm according to customers’ requirements. The production capacity and efficiency will be 30%-40% more than other brand machines.

- This machine will eliminate greasy environment, because there is no greasy yarn occur.

- This machine will save 20% power than other brand machines.

9.The production capacity and spinning process and the bobbin yarn standard weighting will be display on machine screen automatically.

10.The internet and WLAN connection points are available on this machine; it can be supervised by internet.

Machine Picture:

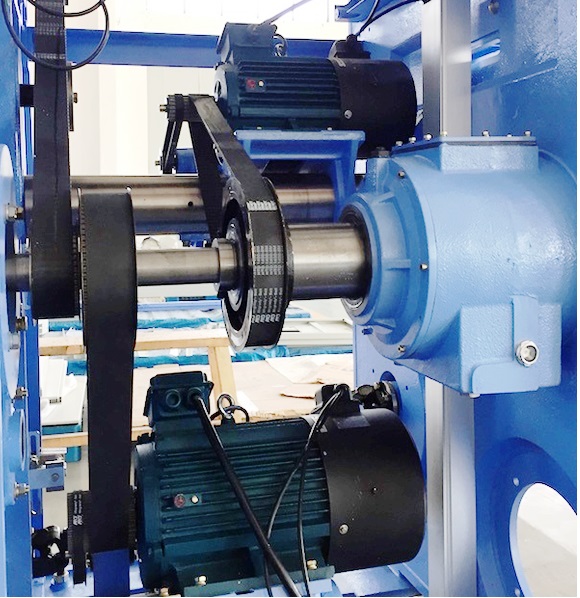

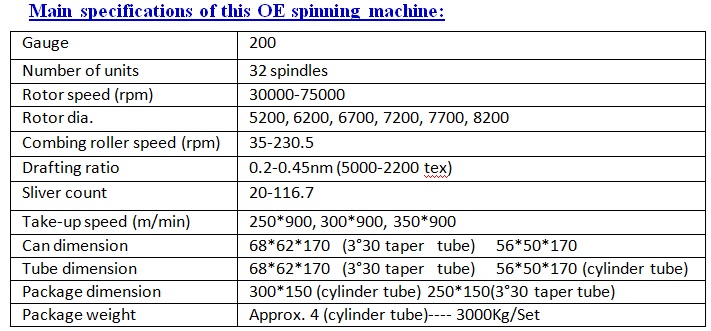

ROTOR SPINNING MACHINERY

Product Description:

Based on referring advance technology of other domestic Rotor spinning frame, HJF1603 rotor spinning frame is a sort of high speed, efficient, large package

Function and characteristics:

*PLC control, Stable running and long service life

*This machine adopt new techniques such as the new type suction spinning unit and the horizontal automatic piecing device, resulting in the maximum speed of the *One can put shaping or select the toper tube for use for the parallel tube *Furnished with and fall one suck yarn device, in full yarns fall one produce and stay tail yarn, make the yarn able to retreat and wind in succession *Good operation interface, control and display every technology parameter in real time

Machine Picture:

1. TD- 1603 Rotor Spinning Machine Open End Spinning Machine:

Machine Picture:

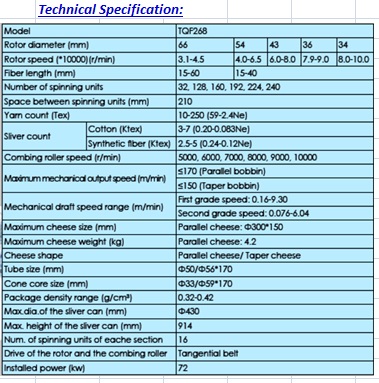

2. TQF268 ROTOR SPINNING FRAME

Machine Picture:

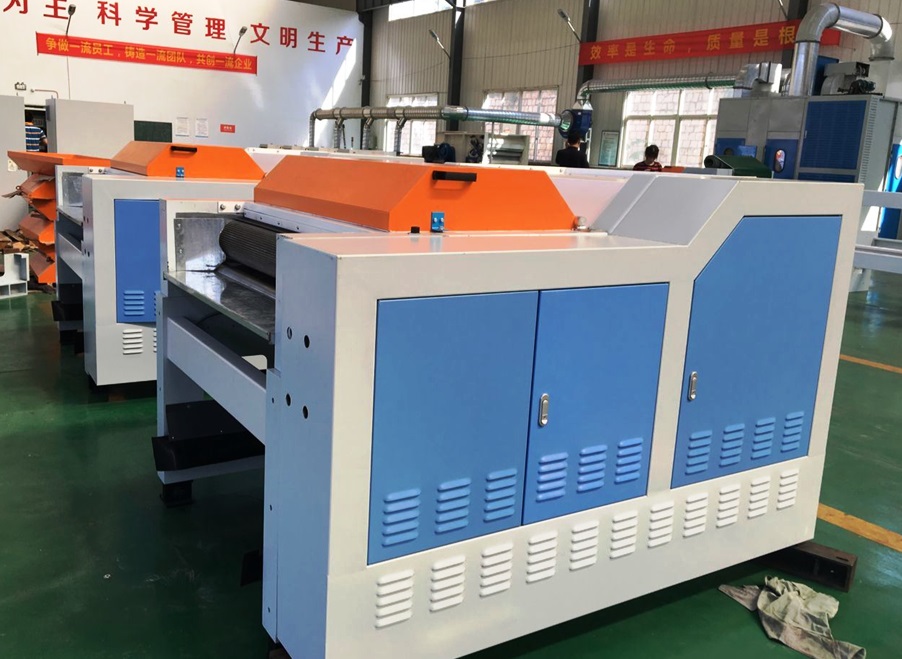

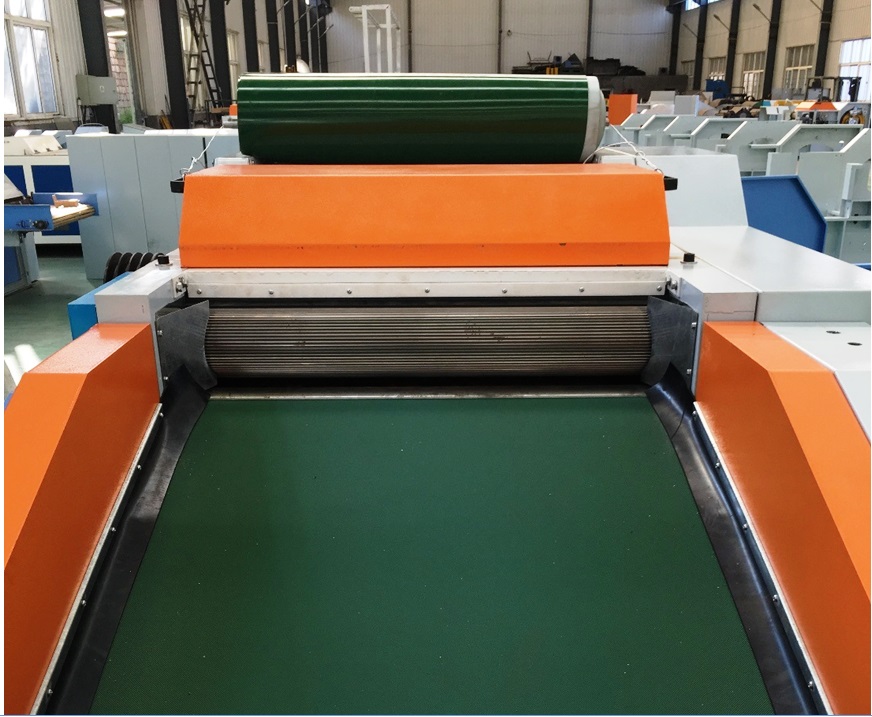

WASTE RECYCLING MACHINE:

1.Tdfs400 Recycling Machines for Cotton Waste:

Application:

- This machine is used to tear the waste cloth into small pieces & remove the impurities in the cotton using mechanical centrifugal force emerged by the high speed revolving of the barbed rollers and the fluffs and splits the cotton.

- It is the ideal to process the textile cloth waste, spinning yarn waste etc. It can lose the fabric waste, hard waste, prepare for further process by textile waste recycling machine series. Also it can help to keep the fiber length of the finished product, reduce the damage to the wire of the machine series.

Product Description:

Porcupine roller with diameter 600-1000mm, each cylinder with difference angle and specifications taper-pins, the feeding roll adopted elastic rubberized roller with diameter 150-250mm. The working width from 1000-2000mm and the maximum capacity up to 2500kg per hour. With pneumatic brake system and lubricating system, direct driving system with the gear motor without chains driving system and installation, this line reduce the damaging of the fiber, in order to keep the fiber length. The porcupine roller will be changed according to raw material and customer requirement.

Advantages:

1) With pneumatic brake system and lubricating system, direct driving system with the gear motor without chains driving system

2) Reduce the damaging of the fiber and keep the fiber length.

3) The porcupine roller will be changed according to raw material & customer requirement.

4) Full automatic, save manpower.

5) Efficient and environmental protection

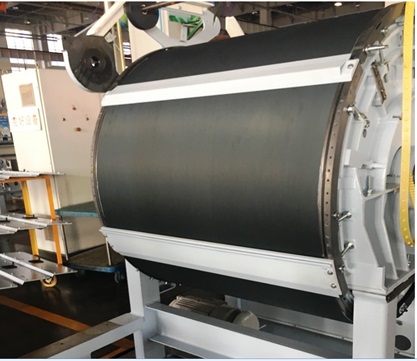

Machine Picture:

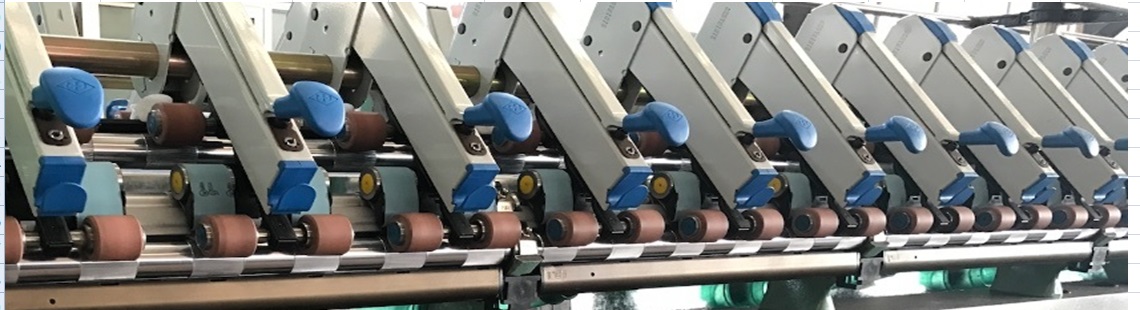

WINDING MACHINE

- Auto Coner Auto Winding Machine for Cotton Spinning Machine Line:

Description of Machine:

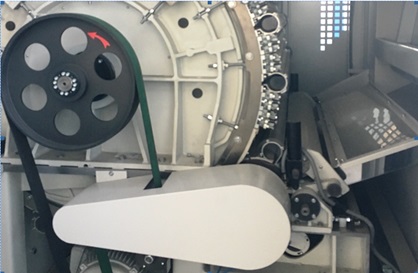

SMARO-NEW automatic winder inherits the advantages of Smaro series winder, adopts brand-new profile design, featured by beautiful and dignified, adopts and dignified, adopts the brand-new smart anti-pattering device, new type of tension control system and new type of balloon control mechanism to ensure perfect package building, more even winding tension, high machine operation stability and reliability to meet customer requirement.

Advantages:

i). Anti-patterning system: New type of electronic anti-pattering system, adopting balance pressure regulating in ratio, functions during the whole winding process to eliminate the

.(ii). Closed drum cover New type of closed drum cover can efficiently prevent package yarn tail from throwing off, greatly reduce yarn wrap on small bobbin side, prevent bobbin building problem, enhance one-time head suction successful rate, Electronic anti-wrap drum can prevent yan wrap on drum and stepped winding yarn, optimize package building and reduce material waste.

(iii). Close-loop control Newly increased tension close-loop control ensures even doffing tension; enhance winding speed 10-20% and production efficiency 2-5%.

(iv). DC brushless motor Comparing with traditional belt drive, DC brushless motor coaxial drive winding drum could reduce the electricity consumption and improve the productivity due to the elimination of the power loss caused by belt friction and slipping.

(v). Electronic clearer controls Electronic clearer controls yarn quality, including yarn joint quality, during the whole winding process, two different yarn cleaner settings are adopted for normal yarn winding and joint respectively. The most advanced electronic yarn models can be equipped. Foreign fiber detecting function can be close as optional.

(vi). Splicing system Splicing system adopts modular-design for easy installation and maintenance. Different types of splicers can be interchanged according to different customer requirement.